Hydraulic Presses and Robotic Automation

June 20, 2023Comments

Greenerd Press & Machine Co.

Booth D40833

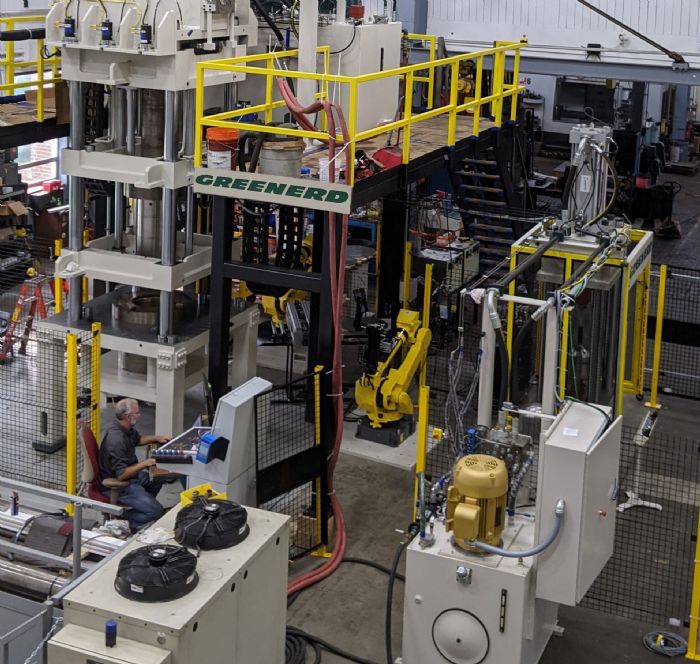

Greenerd Press & Machine Co. will showcase its hydraulic

press and automation capabilities at FABTECH, and have application experts and

design engineers available to discuss specific user applications and press

requirements. Shown here: an automated two-press, two-robot production cell

that Greenerd designed, engineered, built and turnkey-installed that enables

unattended production of large aluminum pressure vessels. Using sensors to

locate pallets of blanks that have been placed in a pallet staging area, the

first robot picks a blank, detects and rejects any double-blanks, and transfers

the blank to a fully integrated and automated lube station. The robot then

picks a previously lubricated blank and loads it into a Greenerd deep-draw

press with a 76-in. stroke. A second robot catches and transfers formed parts

to a second Greenerd press for a punching operation.

Greenerd Press & Machine Co. will showcase its hydraulic

press and automation capabilities at FABTECH, and have application experts and

design engineers available to discuss specific user applications and press

requirements. Shown here: an automated two-press, two-robot production cell

that Greenerd designed, engineered, built and turnkey-installed that enables

unattended production of large aluminum pressure vessels. Using sensors to

locate pallets of blanks that have been placed in a pallet staging area, the

first robot picks a blank, detects and rejects any double-blanks, and transfers

the blank to a fully integrated and automated lube station. The robot then

picks a previously lubricated blank and loads it into a Greenerd deep-draw

press with a 76-in. stroke. A second robot catches and transfers formed parts

to a second Greenerd press for a punching operation.

The two-press production cell uses a centralized control station that sets the operating parameters of both presses and controls the action sequences of both robots. All equipment in the cell is automatically updated with new process parameters when changing between products.