Remote, Web-Based Robot Control and Error Recovery

May 13, 2024Comments

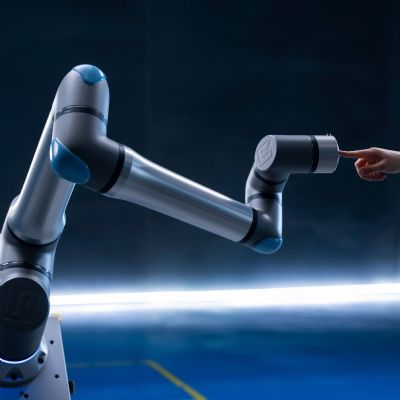

Olis Robotics specializes in remote control and error

recovery systems for industrial robots, with its Olis Connect system allowing

users to monitor, diagnose and remotely control robots from anywhere. The edge-hosted

product facilitates remote control and low-latency video feeds for industrial

robot arms, and via its web interface can move a robot out of its error

position, release its grip on a part causing a problem, or even use the robot

to remove a bad part from a machine. The system allows for fast and simple error

recovery for robots that, according to company officials, returns a

manufacturing process back to production in minutes instead of hours or days.

Olis Robotics specializes in remote control and error

recovery systems for industrial robots, with its Olis Connect system allowing

users to monitor, diagnose and remotely control robots from anywhere. The edge-hosted

product facilitates remote control and low-latency video feeds for industrial

robot arms, and via its web interface can move a robot out of its error

position, release its grip on a part causing a problem, or even use the robot

to remove a bad part from a machine. The system allows for fast and simple error

recovery for robots that, according to company officials, returns a

manufacturing process back to production in minutes instead of hours or days.

Controlled directly in a web browser and delivered on an edge-hosted PC, Olis Connect connects quickly to new and legacy industrial robot arms and robotic cells. The system works across robot brands, with Olis Robotics providing full support for robots from such companies as Universal Robots, Fanuc and Kawasaki.

Once the plug-and-play device is installed and secure remote access has been configured, users can monitor and manage automation remotely from anywhere via any browser-capable device. Should a robot problem occur, Olis Connect sends out an alert via a secure connection to the user’s device all without connecting to the cloud. Users then use the system to remotely perform error-recovery actions such as releasing its grip on a part or moving the robot from its error position. Three cameras provide low-latency monitoring of an entire robotic cell, enabling 24/7 measurement of key performance indicators such as OEE and instant, on-demand video replay to forensically diagnose the root cause of any error. Importantly, according to company officials, Olis Connect is designed to provide remote access without violating the robot’s existing safety permissions and restrictions, meaning that velocity, acceleration and joint-limit settings on the robot are always obeyed when remote controlling the arm.

At Automate 2024, recently held in Chicago, IL, Kawasaki provided a full-featured technology display via its partner CRG Automation, showcasing multi-SKU palletizing and depalletizing using a Kawasaki BX130X robot and an automated application using an RS007L robot, with Olis Connect providing remote control and monitoring of the entire system.

See also: FANUC America, Inc., Kawasaki Robotics, Universal Robots, Olis Robotics

Technologies: Pressroom Automation