Stamping Presses and Shut Height—What Every Tooling Engineer Should Know

February 25, 2025Comments

During the past year, most of my monthly columns have addressed “What Every Press Technician Should Know.” Topics have included counterbalance pressure, off-center loading, reverse tonnage, feed-release timing, setting small dies in large presses, and die-setting fasteners and clamping. Of course, these topics also are important for die designers and tooling engineers.

Die designers and tooling engineers also must consider additional topics to ensure successful production runs, optimum die life and reduced press maintenance. Releasing stamping dies for production without considering these factors makes it extremely difficult for even the best press technician to succeed.

Influence of the Press

Die designers and tooling engineers must understand that a centered “load” and a centered “die” are not the same thing. Forces in a stamping die not distributed evenly across the press slide will cause the slide to tip and move laterally in the direction of the greatest force. Such movement occurring with punches engaged with other die components can cause excessive wear or damage.

Also important: the tonnage rating of a press. The available tonnage decreases in mechanical presses as the working distance above bottom dead center increases. This derating of tonnage occurs because the relationship between the shaft angle and the pitman has reduced mechanical advantage higher up in the stroke. This holds true for flywheel-driven mechanical presses and their servo-driven counterparts.

A press factor not as well understood as tonnage is working energy. The energy rating of a press is a function of the press load and the distance through which the load must be applied. Energy expends with each stroke of the stamping press and must be replaced prior to the next stroke.

Forming and drawing processes can consume large amounts of press energy due to their long working distances. Even though a press may have adequate tonnage capacity, the die designer/tooling engineer must verify that the press also meets the energy requirements of the process.

Forming and drawing processes can consume large amounts of press energy due to their long working distances. Even though a press may have adequate tonnage capacity, the die designer/tooling engineer must verify that the press also meets the energy requirements of the process.

Springback Compensation

A correctly set die shut height for the material thickness being formed needs no additional adjustments. Far too often, technicians will alter die shut height to compensate for die-timing issues, such as a stencil hitting too hard or a bent flange that is sprung-open or overbent.

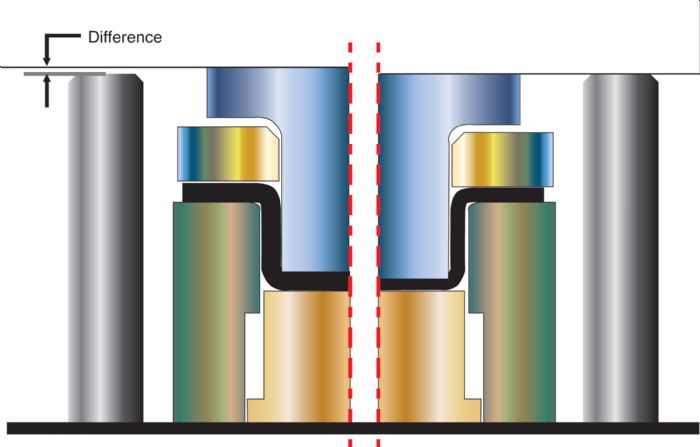

The inside shut height of the die shown in Fig. 2 illustrates the impact that material thickness can have on dies with bending and forming stations that hit their home positions. With a part thickness greater than minimum, the upper-die shoe will not reach the set block when the lower pad reaches its home position, creating a difference in shut height.

The inside shut height of the die shown in Fig. 2 illustrates the impact that material thickness can have on dies with bending and forming stations that hit their home positions. With a part thickness greater than minimum, the upper-die shoe will not reach the set block when the lower pad reaches its home position, creating a difference in shut height.