EOS, Oak Ridge National Lab Sign R&D Agreement on In-Situ Monitoring

August 9, 2022Comments

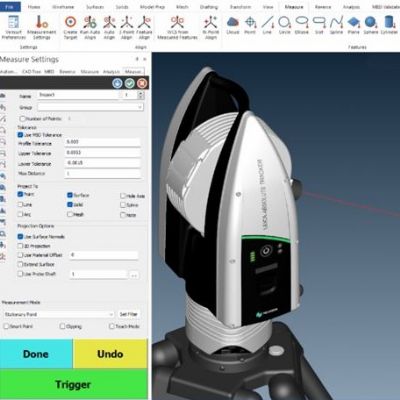

EOS has reached a 2-yr. Cooperative Research and Development Agreement (CRADA) with the U.S. Department of Energy for a collaborative research project at Oak Ridge National Laboratory (ORNL) involving in-situ monitoring. The agreement includes an onsite EOS M 290 metal 3D printer and training for ORNL researchers on operation and data collection using Eostate MeltPool monitoring software.

Using on-axis sensors integrated into the beam path, the software measures the emissions of the melt pool to provide insight into the 3D printing process, with various individually adjustable analysis parameters enabling evaluation of part quality. This technology will assist as ORNL is developing and testing its own inspection techniques to identify new methodologies and approaches for quality assurance in additive manufacturing (AM).

“As AM continues to generate greater levels of appeal for mass production, there is a growing requirement to ensure quality, and build upon one of the greatest strengths of 3D printing, which is the capability to monitor parts as they are being built, layer-by-layer,” says Dr. Ankit Saharan, senior manager, metals technology at EOS. “If we can improve quality-control processes to the point of making adjustments to builds in real time, as anomalies are detected, that will save organizations time and energy while improving overall quality control.”

ORNL’s research will leverage several defect- and anomaly-detection processes to assess the accuracy of these methods in sample builds. ORNL has been working to develop a characterization methodology using computed tomography to identify defects and anomalies in 3D-printed builds. To accomplish this, researchers will use two Eostate MeltPool monitoring and Eostate Exposure optical-tomography methodologies.