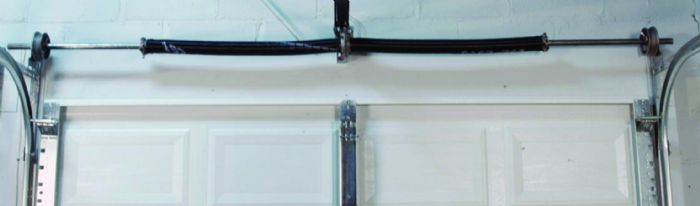

When replaced, garage-door springs also are adjusted to counterbalance the weight of the door. When properly adjusted, the door can be closed to the halfway position easily and held there with little effort (Fig. 2). Stopping the garage door’s upward or downward movement can be accomplished quickly and with little force.

When replaced, garage-door springs also are adjusted to counterbalance the weight of the door. When properly adjusted, the door can be closed to the halfway position easily and held there with little effort (Fig. 2). Stopping the garage door’s upward or downward movement can be accomplished quickly and with little force.

We look for these same attributes in a press ram: easily lists and closes, stops quickly with little effort, and is held easily in its stopped position.

Press Counterbalance Systems

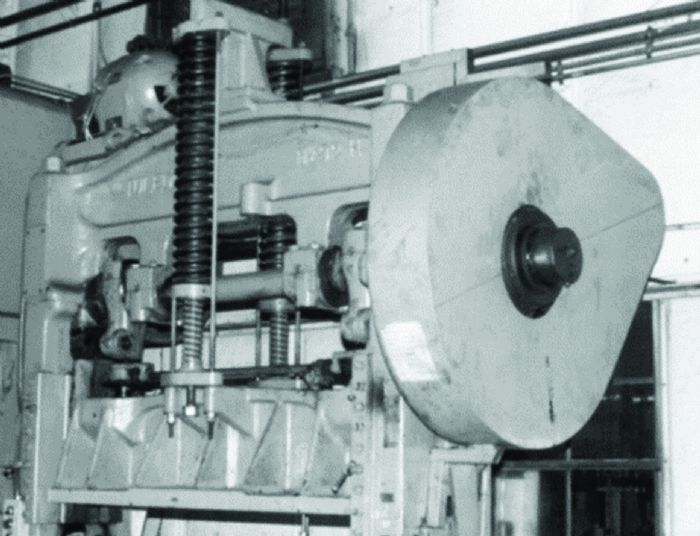

Coil-spring counterbalances in older power presses served a similar purpose as coil springs on garage doors (Fig. 3). These springs were adjusted until the press ram, with its die attachments, would hold at midstroke (90-deg. rotation) without the brake applied.

Today, air counterbalance systems represent the most common method of counterbalancing mechanical power presses. These systems require the press technician to adjust a pressure regulator to a value that will neutralize the weight of the slide and its upper attachments. Most presses include a chart attached to the press that specifies the correct pressure setting for various upper-die weights. Some presses have an automatic counterbalance-adjustment feature.

A properly adjusted counterbalance allows the shut-height-adjusting motor to rotate the adjustment screws more easily and prevent premature wearing. It also helps to reduce drive-train-gear wear and allow the press to operate more quietly, while also improving stopping time of the press. Safeguarding devices such as light curtains rely on repeatable ram-stopping times to safeguard against injury. Excessive stopping times can render these safety devices ineffective.

A properly adjusted counterbalance allows the shut-height-adjusting motor to rotate the adjustment screws more easily and prevent premature wearing. It also helps to reduce drive-train-gear wear and allow the press to operate more quietly, while also improving stopping time of the press. Safeguarding devices such as light curtains rely on repeatable ram-stopping times to safeguard against injury. Excessive stopping times can render these safety devices ineffective.

Underbalanced Conditions

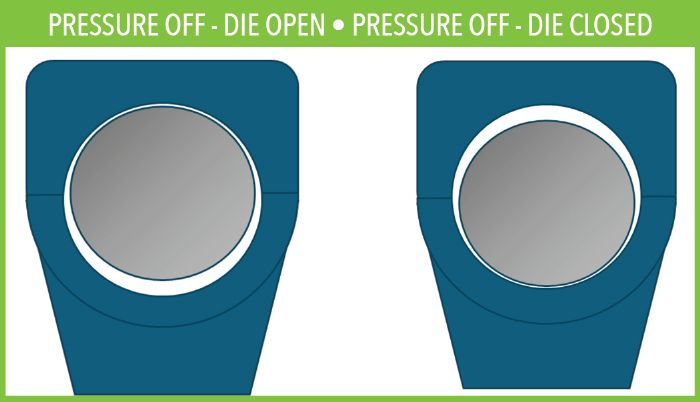

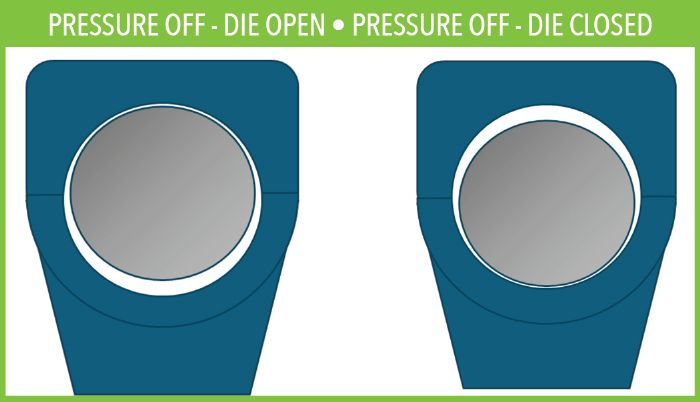

An underbalanced condition occurs due to insufficient air pressure in the system, or due to pressure being completely turned off. Fig. 4 illustrates what happens due to low or no counterbalance pressure. At left, the weight of the pitman connection and ram hang on the shaft journal due to gravity when the ram is at the top if its stroke. The white area between the shaft journal and the connection represents running clearance (for lubrication) between the pitman bearing and shaft. (This has been exaggerated in the illustration for emphasis.)

When the die closes, reaction forces move the ram and its connections upward, taking up the clearance on the underside of the shaft. During production, this translates to constant hammering between the shaft and the press connections that eventually damages the press. Underbalancing also increases ram stopping time, brake wear and force reversals.

A properly balanced system lifts the ram and its connections so that the lower side of the journal stays loaded (excess clearance taken up) throughout the press stroke, eliminating the effects of gravity and reducing hammering of the connection. On the upstroke, the electric motor’s energy serves to regain flywheel speed lost during stamping of the part rather than being wasted on lifting the underbalanced ram.

Overbalanced Conditions

An overbalanced condition occurs when too much upward pressure exerts against the ram. In other words, the counterbalance pressure is set too high. On the down stroke, excessive energy is expended to overcome the counterbalance system. This increases clutch wear (slippage) and motor-current draw while reducing flywheel speed and the corresponding energy left to carry out the stamping operation at the bottom of the stroke. Using our garage-door analogy: Overtightened torsion springs make the garage door almost impossible to close. The torsion springs, trying to maintain the door in the open position, counteract every effort to pull down the door.

How important is counterbalancing? Important enough that OSHA requires that information regarding upper-die weight be made available to the die setter to enable proper counterbalance adjustments. The required method: stamping the upper- and total die weight on the die unless the company can show a foolproof alternative such as readily available written instructions—including the upper-die weight. MF

Technologies: Stamping Presses, Tooling

A press technician is more than an operator. A technician comprehends stamping processes in terms of degrees of rotation, feed angles, sensor-signal angles, feed velocity, pressure requirements, signal lag time and other technical aspects necessary to effectively set up and run a modern press line.

A press technician is more than an operator. A technician comprehends stamping processes in terms of degrees of rotation, feed angles, sensor-signal angles, feed velocity, pressure requirements, signal lag time and other technical aspects necessary to effectively set up and run a modern press line. Press-ram counterbalance systems can be found on all but the smallest presses. The purpose of the counterbalance system: offset or neutralize the weight of the press ram, its connections and the upper-die assembly.

Press-ram counterbalance systems can be found on all but the smallest presses. The purpose of the counterbalance system: offset or neutralize the weight of the press ram, its connections and the upper-die assembly.

When replaced, garage-door springs also are adjusted to counterbalance the weight of the door. When properly adjusted, the door can be closed to the halfway position easily and held there with little effort (Fig. 2). Stopping the garage door’s upward or downward movement can be accomplished quickly and with little force.

When replaced, garage-door springs also are adjusted to counterbalance the weight of the door. When properly adjusted, the door can be closed to the halfway position easily and held there with little effort (Fig. 2). Stopping the garage door’s upward or downward movement can be accomplished quickly and with little force.  A properly adjusted counterbalance allows the shut-height-adjusting motor to rotate the adjustment screws more easily and prevent premature wearing. It also helps to reduce drive-train-gear wear and allow the press to operate more quietly, while also improving stopping time of the press. Safeguarding devices such as light curtains rely on repeatable ram-stopping times to safeguard against injury. Excessive stopping times can render these safety devices ineffective.

A properly adjusted counterbalance allows the shut-height-adjusting motor to rotate the adjustment screws more easily and prevent premature wearing. It also helps to reduce drive-train-gear wear and allow the press to operate more quietly, while also improving stopping time of the press. Safeguarding devices such as light curtains rely on repeatable ram-stopping times to safeguard against injury. Excessive stopping times can render these safety devices ineffective.