Featured Content

Seyi's SDN1 Advanced Gap Frame Servo Press

September 10, 2024 Comments

In 2024, SEYI-America released the SDN1 series, the most technologically advanced gap frame servo press.

The SDN1 series features a new-generation direct-drive servo motor that enhances smaller stamping processes. It's designed to offer higher productivity and better product quality through increased stroke speed and improved slide movement. With its high precision, rapid speeds, and C-shaped body type, the press brings new possibilities to the table for manufacturers.

The SDN1 series features a new-generation direct-drive servo motor that enhances smaller stamping processes. It's designed to offer higher productivity and better product quality through increased stroke speed and improved slide movement. With its high precision, rapid speeds, and C-shaped body type, the press brings new possibilities to the table for manufacturers.

Available in models ranging from 88 to 275 tons, the press is standard with the following features:

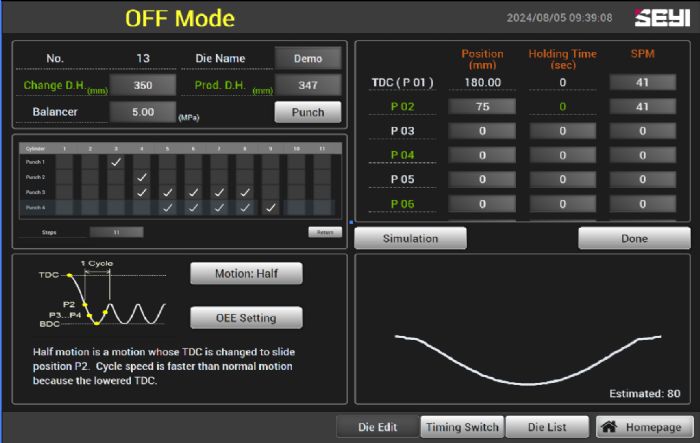

- 7 Default Motion Profiles and 1 Free Motion

- 200 Job Recipe Storage

- Easy-to-use Swing Arm Mounted HMI

- Re-Circulating Lubrication

- Electronic Overload Protection

- T-Stand with Handy Pulser Wheel

- Tonnage Monitor

- 15 Programmable Limit Switch Outputs

- 8 Die Protection Inputs

View a complete list of standard and optional features.

When is the SDN1 Right for You?

When it comes to churning out millions of small parts that have lower tonnage requirements, there is no better press for the job. With its adjustable stroke and the ability to run half-motion, manufacturers can transform their stamping operations.

The SDN1 is ideal for various manufacturing scenarios, particularly when flexibility and efficiency are critical. If your production involves intricate parts with tight tolerances, such as electronics, medical devices, or fine mechanical components, a servo gap frame press can deliver the necessary accuracy and repeatability.

The SDN1 is ideal for various manufacturing scenarios, particularly when flexibility and efficiency are critical. If your production involves intricate parts with tight tolerances, such as electronics, medical devices, or fine mechanical components, a servo gap frame press can deliver the necessary accuracy and repeatability.

Additionally, the SDN1 can optimize smaller progressive dies with high outputs. With the ability to shorten the stroke with half-motion, the SDN1 will consistently outperform a traditional mechanical press. Appliance, automotive, and electronic stamping parts often fall into this category.

Webinar

Webinar