seen at fabtech

Electromagnetic Quick, Safe Die-Clamping System

November 19, 2024Comments

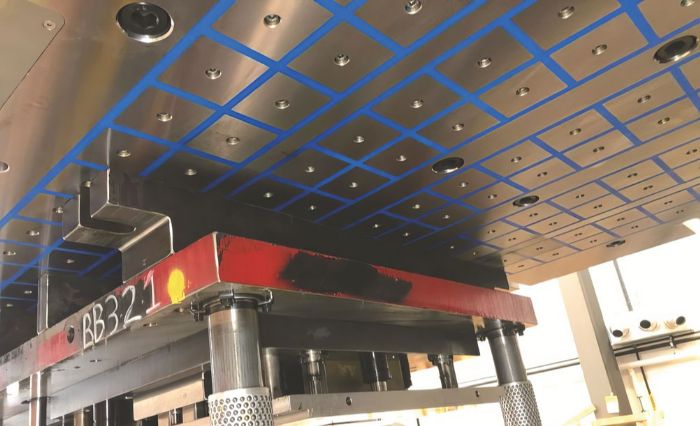

Soph featured the Magbo MBS electro-permanent magnetic

quick-die-clamping system for stamping presses, suitable for suitable for die

plates, die shoes, quick-die-change plates or parallels of any size with no

modifications, thus delivering savings in engineering time and overall cost.

Soph featured the Magbo MBS electro-permanent magnetic

quick-die-clamping system for stamping presses, suitable for suitable for die

plates, die shoes, quick-die-change plates or parallels of any size with no

modifications, thus delivering savings in engineering time and overall cost.

Needing only a single operator and no tools, MBS in a few

seconds with the press of a

button enables safe die clamping and unclamping. MBS offers locating devices and

bolster extensions that easily can be added, and scrap holes can be used. The

system provides uniform clamping with as much as 12 tons/sq. ft. of force, and

is not affected by electrical breakdowns as the die will stay in position at

the same strength indefinitely even without power supply.

MBS does not magnetize the entire die, company officials explain, as the magnetic flux penetrates the die only to a depth of 20 mm. The die face and part cannot become magnetized, allowing for scrap removal and proper die operation without interference.

New to MBS, a force-reading controller that accurately measures clamping force and enables die identification for as many as 10,000 separate dies.

See also: SOPH, Inc.

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Tooling

ToolingDie Racking Clears Pressroom Clutter

Wednesday, May 28, 2025

Tooling

ToolingRoemheld's Quick-Die-Change Cart

Tuesday, February 25, 2025

Video

Video

Webinar

Webinar