Are We Talking About the Same Thing? What Every Tooling Engineer Should Know

April 23, 2025Comments

Merriam-Webster defines “nomenclature” as the devising or choosing of names for things, especially in a science or other discipline. In essence these are terms that we use to communicate technical ideas or principles to one another, but are we all talking about the same thing?

Accepted nomenclature often tends to be regional. For example, a bonnet in the United States may be viewed as a variety of headpieces sometimes worn by women. In the United Kingdom, it could be interpreted as the hood of an automobile. Another example: a pneumatic pressure system beneath the bolster plate in a stamping press. In North America we commonly refer to this as an air cushion, in the United Kingdom it is called a marquette.

Confusing Press-Shop Terms Abound

Some terms are outright misused—mil, for example. Someone in the press shop states that something is 1 mil thick. Do they really mean 1 mil thick or do they mean 1 millimeter thick? Contrary to common belief, these values are not the same. One mil equals 0.001 in. in thickness; 1 millimeter equals 0.03937 in. Not convinced? Is that 3-mil trash bag in your garage really 0.118 in. thick?

Some terms are outright misused—mil, for example. Someone in the press shop states that something is 1 mil thick. Do they really mean 1 mil thick or do they mean 1 millimeter thick? Contrary to common belief, these values are not the same. One mil equals 0.001 in. in thickness; 1 millimeter equals 0.03937 in. Not convinced? Is that 3-mil trash bag in your garage really 0.118 in. thick?

The terms “punch” and “die” often are misinterpreted, primarily because they contain double meanings. For example, a complete stamping tool often is referred to as a die, and the individual that built it, a die maker. The die consists of two main halves: the upper die, often called the punch; and the lower die, often referred to as the die. However, consider that the punch also may refer to one or more male forming or cutting components, which may mount to either the upper punch shoe or the lower die shoe. When the die is mounted to the punch and the punch to the die, it all becomes very confusing.

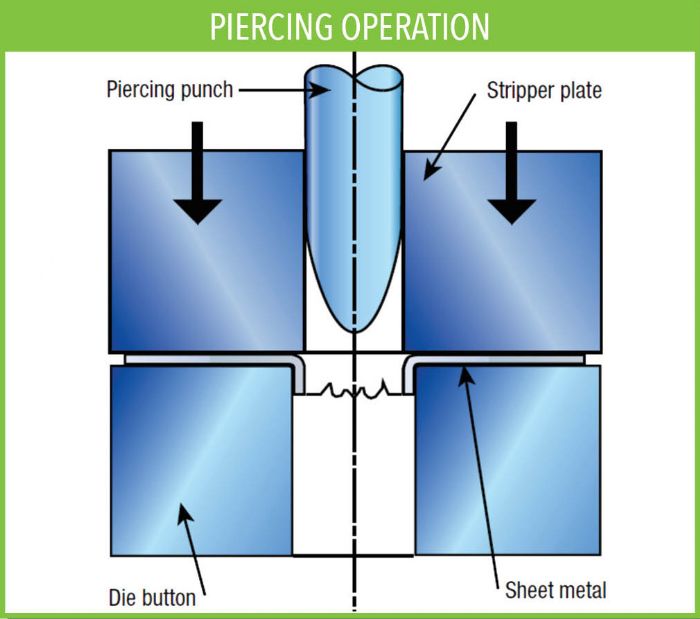

Another source of confusion involves the terminology used for making holes. Are they punched or pierced? To differentiate between punching and piercing, consider that punching operations produce slugs while piercing operations do not. Or, consider that piercing a steak with your fork does not produce a slug, nor does ear piercing.

Piercing operations frequently are defined as “forming a hole in sheet metal with a pointed punch with no metal fallout.” The figure depicts a piercing operation fitting this description.

Steel Descriptions Demand Consistency

Nomenclature defined through national or international standards organizations for one industry often are misused by other industries. The steel-producing industry (steel mills) and steel users (metal formers) offer a good example.

Webinar

Webinar