Soon after World War II, the numerical control (NC) machine was developed. NC machines used a series of holes punched on paper tape or punch cards to control their motion. In the 1960s, computers were added to give even more flexibility to the process. Such machines became known as computerized numerical control (CNC) machines. NC and CNC machines could repeat cutting sequences precisely, and produce more complex shapes than even the most-skilled tool makers.

The last half of the 20th century saw traditional job shops transform into specialized tool shops that produce only one type of tooling. This trend can be attributed to the growing sophistication of tooling plus the fact that shops with the skills and equipment necessary to fabricate one type of tooling were seldom equipped for another. Tool and die making has become further specialized to the point that many limit themselves to dies with special applications such as high-speed (carbide) progressive die, or industries such as aerospace or automotive.

Today’s Tool and Die Shops

The North American tool and die industry consists primarily of small businesses using skilled employees having many years of experience. According to the U.S. Bureau of Labor Statistics data, nine out of 10 tool and die industry firms employ fewer than 50 workers. These companies generally are privately owned and often family operated.

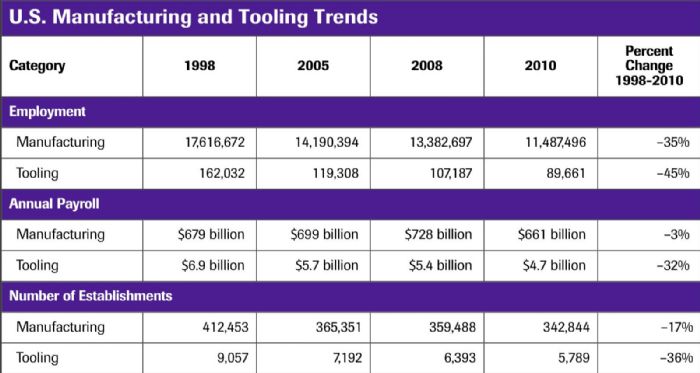

Between 1998 and 2010, the number of U.S. manufacturing establishments declined by 17 percent while the number of tool and die establishments dropped by 36 percent. This is more than twice the rate of decline of manufacturing establishments (see the accompanying table).

In 2022, manufacturing employment rose to 12.58 million jobs—a 22-percent increase since 2010. During the same period, tooling jobs fell to 58,590—an additional 35-percent decline since 2010. Part of the problem is that high school and vocational school students are not interested in manufacturing apprenticeship opportunities. Individuals seeking apprenticeship opportunities often choose construction trades instead.

A lack of interest in tool and die careers has forced many tool and die shops to find other ways to produce their products, primarily by increasing the use of more automated equipment. In some companies, “lights-out” manufacturing has become the norm: A night shift is run with minimal or no worker involvement. In the absence of skilled workers and with the emergence of artificial intelligence and machine learning technology, highly automated die manufacturing likely will increase.

Although tool and die firms are small in number and total employment, they play a vital role in manufacturing innovation. Any durable-goods manufacturer seeking to introduce a new product is likely to require customized tools, dies and molds to make metal, plastic and ceramic components. While most tool and die production is used to make durable goods for the consumer market, this industry also plays an important role in manufacturing military and aerospace equipment such as jet aircraft, missiles, tanks, electronics and satellites.

The tool and die industry always has been subject to economic swings and foreign competition, but the rise of China’s manufacturing sector during the past 25 years has brought additional stress. Foreign competition, application of new technologies and two recessions caused a loss of nearly half of all tool and die establishments since 1998 and a reduction of the workforce by more than 60 percent.

U.S. durable-goods manufacturing appears to be reviving and reshoring existing jobs from overseas is benefiting U.S manufacturers and tool and die makers. But ongoing technological changes are required for tool and die shops to operate differently than in the past and will require a workforce with very different skill sets. MF

Technologies: Software, Tooling

In Whitney’s concept, each component was produced to prescribed dimensions with the aid of tooling, so that highly skilled craftsmen previously required for manufacturing no longer were needed as no additional fitting or selective assembly of the parts was necessary. Whitney’s tooling consisted of templates (tool-guiding patterns) and rudimentary fixtures—the precursor to today’s tools and dies. He and his company successfully demonstrated the feasibility of manufacturing interchangeable parts by mass-producing firearms for the War of 1812.

In Whitney’s concept, each component was produced to prescribed dimensions with the aid of tooling, so that highly skilled craftsmen previously required for manufacturing no longer were needed as no additional fitting or selective assembly of the parts was necessary. Whitney’s tooling consisted of templates (tool-guiding patterns) and rudimentary fixtures—the precursor to today’s tools and dies. He and his company successfully demonstrated the feasibility of manufacturing interchangeable parts by mass-producing firearms for the War of 1812.