4. What are an air feed’s advantages?

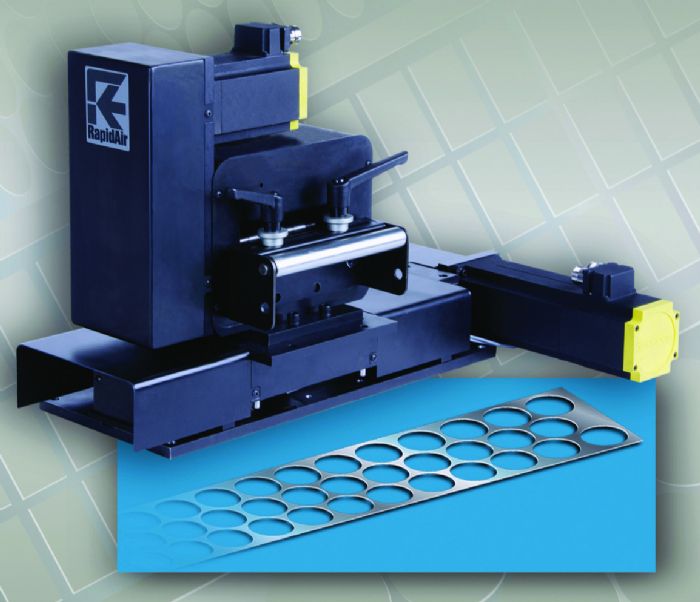

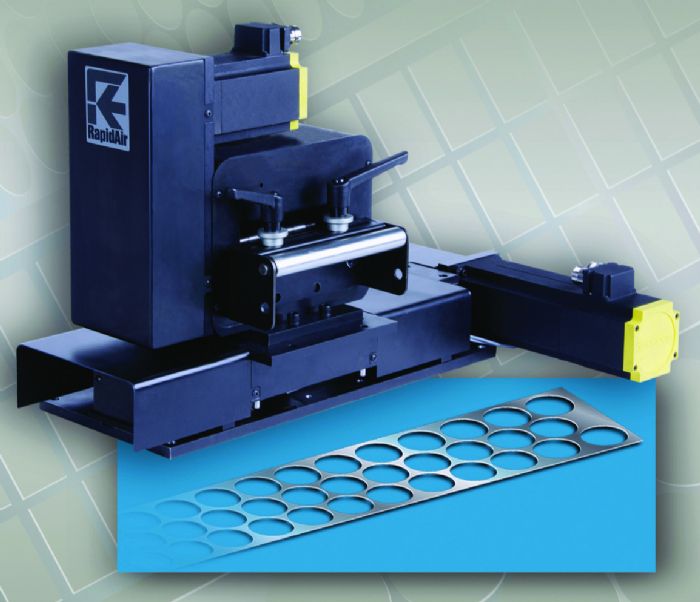

Versatile air feeds offer great flexibility when feeding various shapes because they can feed unusual shapes in unusual positions. Air feeds handle thin and delicate materials well. In addition, metal formers can feed various materials in any direction. An air feed potentially provide a large grip area with clamps.

Because it has a small envelope, an air feed can be mounted on the bolster plate or die to push or pull material through the die. Its low price tag often justifies permanent installation on die sets to minimize job-setup time. Die-mounted feeds facilitate quick changeover, reduced setup time and no required alignment of feed to die.

5. What are an air feed’s disadvantages?

Progression or feed-length changes can be time-consuming, requiring hand tools and trial and error.

In addition, an air feed requires vigilant maintenance because it must have a constant volume of high-quality air. Excess oil, dirt and water in the air will shorten feed life and inhibit function, and fluctuating air volume will cause erratic feeding. Repair requires complete disassembly and installation of new O-rings and seals. Fortunately, maintenance can be completed simply, inhouse, or a feed manufacturer or distributor can perform the overhaul.

Air feeds generally run best with flat material, so keep an eye on excessive coil set, which may hamper feed motion.

1. Another option for metal formers is a servo feed. How does this type of feed work?

Stampers can speed the feed process by employing programmable servo-motor-driven roll feeds, or servo feeds. Roll release is pneumatic, controlled by a solenoid valve which, in turn, is controlled by the press. Although the press controls can completely take over the servo feed, for the highest level of safety, the press should always control the servo feed. Spring or air pressure controls the feed-roll squeeze.

Stampers can speed the feed process by employing programmable servo-motor-driven roll feeds, or servo feeds. Roll release is pneumatic, controlled by a solenoid valve which, in turn, is controlled by the press. Although the press controls can completely take over the servo feed, for the highest level of safety, the press should always control the servo feed. Spring or air pressure controls the feed-roll squeeze.

Servo feeds can be equipped with additional features, such as feed-roll release for pilot pins or camber correction, for variable circumstances. A servo feed can pair with another machine, such as a shear, for cut-to-length operations.

2. What should stampers consider when setting up a servo feed?

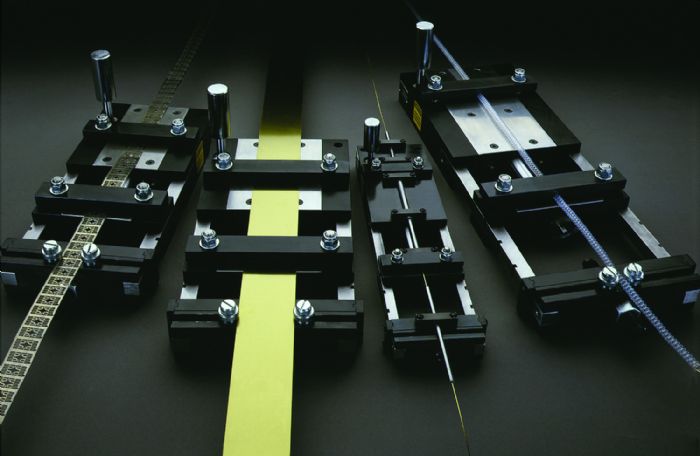

Compact servo feeds boast state-of-the-art controls with features that allow the use of simpler, less expensive dies that may be fed diagonally, side-to-side or in any pattern.

Strip alignment is important on a servo feed, too. Use a tool—something as simple as a carpenter square will work—to check that the strip is square from die to payoff reel. The feed can be mounted to the die, bolster plate, adjustable bracket or stand, and mounting should be rigid and oriented straight into the die. The feed should not push material uphill nor downhill, and electric power should be correctly grounded and free of noise.

Like an air feed, a servo feed must be kept clean, particularly the feed roll and control cabinet. Also, protect cables running from the servo motor to the control cabinet to keep them out of the path of forklift and foot traffic.

Like an air feed, a servo feed must be kept clean, particularly the feed roll and control cabinet. Also, protect cables running from the servo motor to the control cabinet to keep them out of the path of forklift and foot traffic.

Roll size matters, more in terms of deflection than grip. A 2.75-in.-dia. roll will not have significantly more material grip than a 1.75-in.-dia. roll, but it may be large enough in diameter so that it won’t bow or deflect.

For optimal material control, upper and lower feed rolls should be of the same diameter. Both rolls should be driven for optimal grip and accuracy. A small upper roll coupled with a large lower roll is difficult to synchronize.

3. What are a servo feed’s advantages?

A servo feed’s production rate is about twice that of an air feed. Given some basic information related to strokes/min., feed angle, feed length and pilots, the feed will calculate the best acceleration/deceleration and speed. It can store hundreds of jobs, enabling job setup via entering a new job number. This ability to recall a stored job with all of its parameters significantly reduces changeover time, and, therefore, facilitates short runs or frequent job changes.

4. What are its disadvantages?

A servo feed requires a higher initial capital expenditure than an air feed, generally quickly recovered with the increased productivity. It requires a programmable control box equipped with cables to the servo, power supply, press and possibly other components. The control box stores job memory and calculates feed progression, speed, acceleration and timing synchronization with the press.

A servo feed requires a higher initial capital expenditure than an air feed, generally quickly recovered with the increased productivity. It requires a programmable control box equipped with cables to the servo, power supply, press and possibly other components. The control box stores job memory and calculates feed progression, speed, acceleration and timing synchronization with the press.

The rolls’ cleanliness and material composition can be highly critical, depending on the specific application, because a servo feed is in constant contact with the material, similar to how a steam roller constantly contacts the ground. This means that any debris on the rollers constantly touches the material. In contrast, an air feed’s grippers do not contact all of the material as they grip the edge, progress, then release. For that reason, material passing through the rollers can deform under excessive pressure, like a piece of dough.

The grip area of the rolls is relatively small compared to that of an air feed. Therefore, a servo feed’s small grip area may necessitate increasing roll pressure, which, in turn, could deform the material.

Quick acceleration and speeds on a servo feed may cause material slippage, which could lead to inaccuracy.

Feeding extremely light, delicate or thin materials can pose challenges without proper alignment, guides and additional pressure on the rolls, which could also lead to deformation of the material. In such cases, an air feed, with custom guides and clamp materials, may be a more suitable option.

5. What are a servo feed’s best applications?

A servo feed opens options to expand production approaches, such as special feed-roll coatings. Urethane-coated rolls protect painted, polished or soft material, while a roll provided with a matte or knurled finish offers improved grip. Servo feed rolls also can be relieved or profiled to handle unusual material shapes.

Servo stagger feed models are designed to help select the best pattern for round or non-round parts. This reduces material waste because it preprograms the optimal pattern and allows the use of irregular-width coil. Servo feeds with a gag program allow a pattern of changing feed lengths with outputs for punch control, and gag programs can be customized.

A tandem servo feed, with an entrance and exit servo to grip and synchronize the material, offers another approach to feed thin or flexible material. Electronic gearing between the two feeds maintains light tension on the material.

Be sure to match the feed capacity to the job for the best performance. Consider the preponderance of jobs, stock thickness, stock width and speed in your operation. Review the operating manual—available online from most manufacturers—to ensure the most accurate match of your job specifications to the optimal equipment. MF

See also: Rapid Air Corporation

Technologies: Coil and Sheet Handling

In brief, company founder Richard Nordlof invented and pioneered the first air feed in the late 1950s. At that time, mechanical hitch feeds were the norm, but their accuracy and dependability were in question in many applications. While they were effective for many tasks, they lacked versatility. A company’s customer, Parker Pen, originally in Janesville, WI, sought a faster and more accurate feeding solution, which led to experimentation.

In brief, company founder Richard Nordlof invented and pioneered the first air feed in the late 1950s. At that time, mechanical hitch feeds were the norm, but their accuracy and dependability were in question in many applications. While they were effective for many tasks, they lacked versatility. A company’s customer, Parker Pen, originally in Janesville, WI, sought a faster and more accurate feeding solution, which led to experimentation.

Stampers can speed the feed process by employing programmable servo-motor-driven roll feeds, or servo feeds. Roll release is pneumatic, controlled by a solenoid valve which, in turn, is controlled by the press. Although the press controls can completely take over the servo feed, for the highest level of safety, the press should always control the servo feed. Spring or air pressure controls the feed-roll squeeze.

Stampers can speed the feed process by employing programmable servo-motor-driven roll feeds, or servo feeds. Roll release is pneumatic, controlled by a solenoid valve which, in turn, is controlled by the press. Although the press controls can completely take over the servo feed, for the highest level of safety, the press should always control the servo feed. Spring or air pressure controls the feed-roll squeeze.  Like an air feed, a servo feed must be kept clean, particularly the feed roll and control cabinet. Also, protect cables running from the servo motor to the control cabinet to keep them out of the path of forklift and foot traffic.

Like an air feed, a servo feed must be kept clean, particularly the feed roll and control cabinet. Also, protect cables running from the servo motor to the control cabinet to keep them out of the path of forklift and foot traffic. A servo feed requires a higher initial capital expenditure than an air feed, generally quickly recovered with the increased productivity. It requires a programmable control box equipped with cables to the servo, power supply, press and possibly other components. The control box stores job memory and calculates feed progression, speed, acceleration and timing synchronization with the press.

A servo feed requires a higher initial capital expenditure than an air feed, generally quickly recovered with the increased productivity. It requires a programmable control box equipped with cables to the servo, power supply, press and possibly other components. The control box stores job memory and calculates feed progression, speed, acceleration and timing synchronization with the press.