Another important requirement was related to press setup, Wunsch says. “We wanted a removable bolster. That created some challenges when it came to passline heights. So, we needed a customized line to support 16 in. of total passline-height travel in the feeder adjustment.”

In March 2024, the company installed a Dallas Industries fully automated, 60-in.-wide conventional line with a DRFH-860 servo feed, an alligator peeler/threader, coil restrictor, a DPS-4-7-60 powered straightener and a 30,000-lb.-capacity reel with load car. For simplified setup, the unit incorporates an adjustable feeder passline height, and automated adjustment of edge guides and coil guide rolls for coil centering. The settings for these axes store in a job recipe called AutoSet.

The line is built on an Allen-Bradley, Ethernet-based control architecture and is equipped with a SyncLoop control that synchronizes the feeder and straightener speeds. The Dallas ProfileSelect feed control employs a cam-motion (sinusoidal) profile designed for a feed motion that uses 100% of the press-feed window, reducing stress on the material and the feed’s mechanical components.

The line is built on an Allen-Bradley, Ethernet-based control architecture and is equipped with a SyncLoop control that synchronizes the feeder and straightener speeds. The Dallas ProfileSelect feed control employs a cam-motion (sinusoidal) profile designed for a feed motion that uses 100% of the press-feed window, reducing stress on the material and the feed’s mechanical components.

“Our recent investment in the new feed line also was driven by safety concerns,” says vice president Cristofer Muchowski. “There is no price that is off limits to us when it comes to our operators’ safety. The holddown/holdup arms, everything to control that coil, expansion of that mandrel … we really asked for some custom features to ensure that we can support all of the coils that we get from our suppliers. All of the sensoring and safety controls in place are very specific to our needs to ensure our operators are safe. There’s a brake control that was a special edition, so that if we lose power to the line, the material will not push forward or fall back out of the die and put our operators at risk.”

Meeting Volume Demands

Manitowoc Tool and Mfg. stamps and fabricates roughly 36.5 million lb. of material/yr. “We move a lot of metal,” Muchowski says.

“Because we have such a diverse customer base, it can be a challenge for us to meet their varying on-time deliveries,” he continues. “Our customers’ expectations are, ‘We need those parts on Monday.’ If we say that we will have them by Wednesday, they call and say, “We need those parts on Monday. What is your recovery plan?’”

The press system and feed line reside at the crux of the company’s highly responsive approach to serving its customers and meeting its high-volume production demands—safely.

The press system and feed line reside at the crux of the company’s highly responsive approach to serving its customers and meeting its high-volume production demands—safely.

Coil storage. One way that Manitowoc meets volume demands is to store ample coil—more than the typical JIT stock. “You can’t start a recovery plan if you don’t have raw material,” Wunsch says. “Typically we house about 6 weeks-worth of material so that we can guarantee customer needs.”

Ready staff. Manitowoc’s 245 employees work in five shifts—the typical three shifts plus a three-12s weekday shift and a weekend shift. “When a customer calls on Friday with an emergency, we can back them up with parts by Monday morning,” says Muchowski. It’s really good to have that for our customers. You can’t put a price tag on that.”

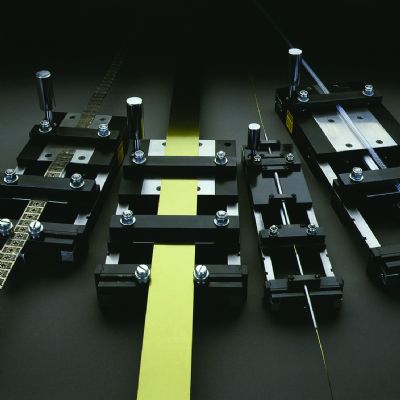

Full tool and die shop. The manufacturer operates three wire-EDM machines to machine die blocks and components, and it heat treats them inhouse. It does not have machinists, however, Wunsch states. “We challenge all of our employees here in our die shop to train to be tool and die makers. Any one of them can walk up to the computer terminals and use AutoCAD,” Wunsch continues. “Machining a block is one thing, but understanding how the block actually fits into the tool assembly … that’s another. That gives us an advantage.

“If a die that we built in this building is damaged, any one of our tool- and die makers have the engineering drawings at their fingertips,” Wunsch adds. “They can start manufacturing that replacement block. We’re able to harden the tooling and in two or three shifts get it running in the press.”

Facility expansion. Manitowoc recently finished building a second facility 3 miles away to house capacity for additional operations to support its growth. The building represents the company’s 13th facility expansion.

Safety. The feed line’s safety features are not a lone effort. They reflect the company management’s overall commitment to safety. “I think this company has a safety record that has hit the ball out of the park,” CEO Scott Mertens says. “As of today, we’ve gone 15 yr. with only one lost-time accident.”

The Net Result, On the Wall

Manitowoc’s trophy case is a “sample wall” showcasing its diverse stampings—evidence of its flexibility and range of capabilities. “If any of our customers question what we’re capable of, here you go,” Wunsch says, pointing to the wall display. “If you want a flat blank with some welded nuts on it, we can do that. You want a cosmetic contoured part? We can do that, too. You want the heavy clunker? We’ve got that one, too. We do everything.” MF

View Glossary of Metalforming Terms

See also: Dallas Industries

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingDallas Industries Delivers Feed Line to Precision Tool & Sta...

October 17, 2024

Coil and Sheet Handling

Coil and Sheet HandlingPress Feed Strong

Kate Bachman Wednesday, April 23, 2025

Coil and Sheet Handling

Coil and Sheet Handling5 Questions About Air Feeds; 5 About Servo Feeds

Bradley Nordlof Thursday, April 17, 2025

Of equal need is having flexible pressfeed lines.

Of equal need is having flexible pressfeed lines. “That can be really challenging,” Wunsch remarks. “We wanted a heavy-duty feed line with backup feed rolls and an alligator peeler table. Safety was a critical concern. We wanted a holdup arm combined with a hold-down arm to rewind coil if necessary. We want to ensure that our operators have the best, safest advantage in rewinding coil.”

“That can be really challenging,” Wunsch remarks. “We wanted a heavy-duty feed line with backup feed rolls and an alligator peeler table. Safety was a critical concern. We wanted a holdup arm combined with a hold-down arm to rewind coil if necessary. We want to ensure that our operators have the best, safest advantage in rewinding coil.”