Flexible Pressroom

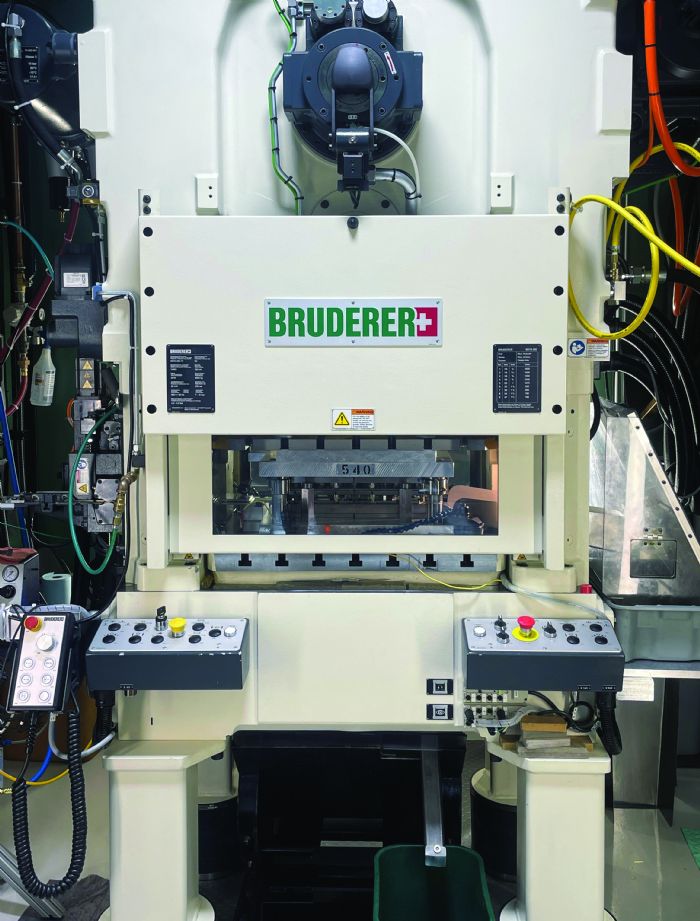

Five machines fill the pressroom at the company’s 90,000-sq.-ft. tech center, with three Bruderer presses providing high-speed capabilities that squeeze the most out of the precision tooling. Two updated 1970s-’80s-vintage Bruderer presses had fulfilled Otto Engineering’s high-speed-stamping needs, but precision and repeatability requirements cited by Trebswether, and the desire to add capacity to meet the company’s ever growing product offerings, necessitated an addition. In 2020, Otto Engineering purchased a new high-speed mechanical press and servo-driven feed from Bruderer, and continues to evolve stamping solutions via this setup.

The 30-ton model 280-75B2 press, with 750-mm bed size left to right, offers the ability to control bottom-dead-center ram position to within 5 microns, and features a semiautomatic adjustable stroke—nine increments from 13 to 47 mm. Due to a unique lever-drive arrangement, the load acting on the ram distributes across the machine, a crucial factor in the press’ high durability and consistent precision, note Bruderer officials. The press pairs with a model BSV 75 servo-driven feed offering a maximum strip width and thickness of 75 and 2 mm, respectively. The feed is suited to high-speed handling of sensitive strip materials and applications requiring long or variable feed lengths. That’s important for Otto Engineering, where strip can be as thin as 0.003 in., and jobs running at speeds to 1000 strokes/min. Bruderer’s B2 control fully integrates the press and feed, including synchronized feed timing via tool and parts data stored in the control’s memory. With its extensive parts library and varying job volumes, Otto Engineering reports control-related benefits of reduced job-changeover time across its roster of 800-plus stamped parts that run in volumes to 350,000. Testament to the company’s tool-design and -build capabilities, and also a changeover aid: some dies may run as many as 40 part numbers, with die sections added or subtracted based on part features. No change of individual components is needed.

The 30-ton model 280-75B2 press, with 750-mm bed size left to right, offers the ability to control bottom-dead-center ram position to within 5 microns, and features a semiautomatic adjustable stroke—nine increments from 13 to 47 mm. Due to a unique lever-drive arrangement, the load acting on the ram distributes across the machine, a crucial factor in the press’ high durability and consistent precision, note Bruderer officials. The press pairs with a model BSV 75 servo-driven feed offering a maximum strip width and thickness of 75 and 2 mm, respectively. The feed is suited to high-speed handling of sensitive strip materials and applications requiring long or variable feed lengths. That’s important for Otto Engineering, where strip can be as thin as 0.003 in., and jobs running at speeds to 1000 strokes/min. Bruderer’s B2 control fully integrates the press and feed, including synchronized feed timing via tool and parts data stored in the control’s memory. With its extensive parts library and varying job volumes, Otto Engineering reports control-related benefits of reduced job-changeover time across its roster of 800-plus stamped parts that run in volumes to 350,000. Testament to the company’s tool-design and -build capabilities, and also a changeover aid: some dies may run as many as 40 part numbers, with die sections added or subtracted based on part features. No change of individual components is needed.

And, in-process control monitoring on the latest press addition enables automatic ram adjustment to maintain correct punch-entry depth based on thermal activity, a technology specifically cited along with other all-automatic press functions by Nacho Lopez, Otto Engineering senior die setter, as an impressive means to prevent tool damage. Feed features include multi-programmable axes that enable staggered, multiple feed lengths in the same stamping process, and pilot-release adjustment via the control’s user interface. Also, a stop-angle-optimized feed window maintains a minimum feed angle to enable control of feed and strip position early on, prior to tool components such as the punch and the pilot pin contacting the strip and causing damage due to incorrect positioning.

Advantages of all of these press, control and feed features are not lost on the stamping team at Otto Engineering. Trebswether and Lopez cite the adjustable stroke, for example.

“We can run a flat part very quickly using a 0.5-in. stroke, for example, and increase the stroke for parts that require forming,” Lopez says. “The adjustable stroke provides the clearance needed to prevent die damage yet allows the press to run at the highest speed possible.”

“We can run a flat part very quickly using a 0.5-in. stroke, for example, and increase the stroke for parts that require forming,” Lopez says. “The adjustable stroke provides the clearance needed to prevent die damage yet allows the press to run at the highest speed possible.”

And, some jobs incorporate in-die tapping, a process that also benefits from the press’ adjustable stroke.

Given its many features, the servo feed delivers flexibility not possible with mechanical feeds, according to Trebswether, particularly the ability to alter feed angles to provide clearance for high-formed parts, or work within a smaller forming window for large, long forms.

Given its many features, the servo feed delivers flexibility not possible with mechanical feeds, according to Trebswether, particularly the ability to alter feed angles to provide clearance for high-formed parts, or work within a smaller forming window for large, long forms.

“Overall, if a part requires 30 tons of force or less and we can fit the die into the bed,” he says, ”we can run almost any job with this press and feed.”

Sophisticated Multi-Material Stamping Process

Otto Engineering keeps its high-speed presses busy to the tune of thousands of tiny parts—weighing fractions of an ounce and measuring fractions of an inch in length—per run, along with frequent job and tool changes. Adding to the precise and voluminous nature of its work is frequent use of multiple materials on single jobs, including some that require multiple feeds.

“We often feed two different materials simultaneously,” Trebswether says, “such as feeding beryllium-copper strip-coil stock through the die, and then inserting a silver wire perpendicular to the die. That job—producing switch contacts for aerospace, agriculture and other control products—runs relatively slower due to feeding the fragile wire, and we employ an air feed attached to the die in addition to the servo feed used for the main strip.”

For other multi-material jobs, Otto Engineering may feed two silver wires along with the strip, or feed a single copper strip with a silver edge, added to the strip by the material supplier and supplied in coil form.

And, some parts undergo unique stamping processes at Otto Engineering due to effects imparted on the final part. For example, Trebswether explained why one tiny beryllium-copper part—acting as a spring that connects to an electrical switch—is cut and formed at a 45-deg. angle to the strip.

“We find that stamping this part parallel or perpendicular to the strip’s grain direction negatively affects the part’s operational life,” he says. “We tried it at a 45-deg. angle to the strip and found that it worked as designed. Instead of this part failing at 120 cycles, by stamping the part at an angle we had hoped to give it a 100,000-cycle life. It actually achieves 130,000 cycles.”

This part also benefits from another idea implemented by the Otto Engineering team. Previously, after removal from the strip the parts were sent out for barrel plating.

“When they came back, we found that we had to scrap 40% of the parts due to damage sustained during the barrel-plating process—nested together and bent out of shape or broken,” Trebswether says. “In addition, during inhouse assembly we found that another 15% were damaged to the point of being out of spec. We decided to try strip plating as an alternative. Though a technology that dates to the 1960s, strip plating was new to Otto Engineering, so we were a bit reluctant. Now via outside plating, the parts on the strip are pulled through a bath and return to us on a reel. When the parts return to us from plating the reels go to the assembly line, which has a small pneumatic press. Assembly-line personnel can set the counter for the amount of parts needed for assembly that day. For example, today we may need to build 1000 switches but tomorrow it may be 1500 switches. The change to change to plating has resulted in part fallout decreasing from 55% to 0.5%.”

Many other parts at Otto Engineering also undergo unique processing. One example: CNC-turned brass parts crimped onto cable. The company stress-relieves these parts in the stamping department’s set of small ovens.

“Without this process,” offers Trebswether, “the parts will crack during crimping.”

And, some parts placed in switches are produced from silver that arrives at Otto Engineering “dead soft,” according to Trebswether, to allow for forming. After forming, the parts route through the ovens at certain times and temperatures to harden them prior to assembly.

“We use these ovens, but don’t have a full setup for heat treatment because we don’t need it,” he says.

Suffice to say that Otto Engineering takes precision, high-speed stamping to another level, especially considering the variety of unique materials it processes as possible. Besides the silver wire, silver-plated bronze and beryllium copper, the company also stamps stainless steel and gold-plated silver—the gold protects the silver from tarnishing, which leads to reduced conductivity.

In sum, Otto Engineering essentially operates as a vertically integrated company—keeping as many processes as possible inhouse in order to ensure quality for the safety-critical parts and products it produces.

Concludes Trebswether: “People’s lives depend on our products.” MF

View Glossary of Metalforming Terms

See also: Bruderer Machinery, Inc.

Technologies: Coil and Sheet Handling, In-Die Operations, Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Stamping Presses

Stamping PressesBruderer Opens New Facility in Telford, UK

Tuesday, April 29, 2025

Stamping Presses

Stamping PressesMidwest Press and Automation to Expand Manufacturing Operati...

Wednesday, March 26, 2025

The firm designs all of its products—including product components—and manufactures them via metal stamping, plastic injection molding, CNC machining and wire EDM. Manual product assembly also is performed inhouse.

The firm designs all of its products—including product components—and manufactures them via metal stamping, plastic injection molding, CNC machining and wire EDM. Manual product assembly also is performed inhouse.