The performance improvement comes from the the abrasive grains perform in service. Grind with a wheel loaded with aluminum oxide and you’ll note large chunks of each grain fracturing a, while ceramic-alumina abrasive is designed to microfracture. As the grains fracture, tiny pieces are expelled to provide a continuous supply of sharp cutting edges. This translates into faster cutting and longer wheel life.

“Grain utilization is the key performance indicator,” says Long. “With aluminum oxide, grain utilization is only 20 to 25 percent. That jumps to 85 to 90 percent for ceramic alumina. While this performance gain pays off when grinding and finishing mild and carbon steels, fabricators will really notice the gain in productivity—fewer wheel changes and reduced labor costs—when working on hard materials such as stainless steels.”

For shops working with softer materials such as aluminum alloys, abrasive-product manufacturers have you covered as well. The key here is to use a finishing product that resists loading, or won’t become “gummed up” with the workpiece material.

“What we’re recommending for aluminum grinding and finishing,” says Long, “are products preloaded with a wax-impregnated coating (Norton Abrasives brought such a product to market late in 2010). The coating fills the gaps between the abrasive grains so that the workpiece material can’t. Shops working with aluminum would be wise to use fiber discs rather than grinding wheels, with this wax-impregnated coating.”

Once you’ve selected the right abrasive for the job, what about the product—wheel or disc? Here, Long recommends first and foremost that fabricators use the right tool for the job. Cutoff wheels, he says, are designed for use on their periphery, reinforced with vertical strength for edge pressure. Don’t try to grind with one. Likewise, grinding wheels, with few exceptions, are reinforced to handle face pressure—don’t try to perform cutoff operations with them. Long does note that manufacturers do offer combination wheels that can cut and grind, but there’s a tradeoff in performance. “The best cutoff wheels on the market today,” he says, “are ultra-thin, 0.040 in., and can’t be used on their face. Kerf is minimal and speed optimum—they’re ideal for cutoff. A combination wheel is thicker, 1⁄8 in. or so. It can grind, but for cutoff the kerf is wider and cutting speed is slower than when using a cutoff wheel. Most users select the ultra-thin wheels for cutoff and a ¼-in.-thick wheel for grinding and finishing.”

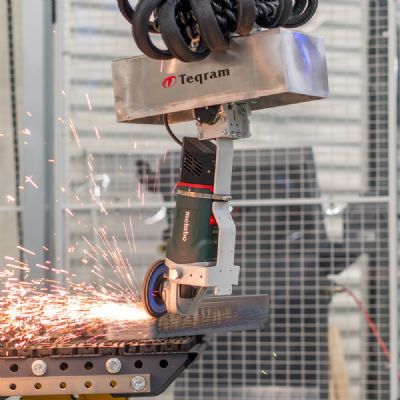

Grinding wheels offer the most aggressive action, for pure metal removal. Select a flap disc for aggressive metal removal and for applications where the ability to grind and finish at the same time is beneficial. “With flap discs,” says Long, “the operator can be steep on the edge of the wheel and remove metal much more quickly than with a grinding wheel. He can then reduce the angle of attack and make nice, wide swaths to impart a smooth surface.”

Also, flap discs, due to their buildup of overlapping abrasive-impregnated flaps, provide a cushioning effect in use. “They’re not as hard-acting as a grinding wheel,” adds Long, “avoiding vibration and optimizing operator comfort.” MFView Glossary of Metalforming Terms

See also: Norton Abrasives

Technologies: Finishing