Cash expects even more ERP benefits as Architectural Fabrication continues to expand via acquisitions, and through software updates recently announced by Rootstock, including to the ERP’s Financials module designed to provide manufacturers a more connected, efficient and insightful approach to financial management. This falls under Rootstock’s Signal Chain strategy that addresses real-time demand signals combined with those coming from the supply chain, augmented with artificial intelligence (AI) to bring functional areas together on one platform, eliminating silos and disjointed sharing of information. The goal of Signal Chain: enable ERP users to make better, more timely decisions that improve manufacturing operations.

“Our latest enhancements foster a user-friendly environment that connects banking and other underlying data streams, so that manufacturers can precisely monitor and manage costs, profitability, cash flow and the overall financial health of their operations,” says Raj Badarinath, Rootstock Software chief product and marketing officer.

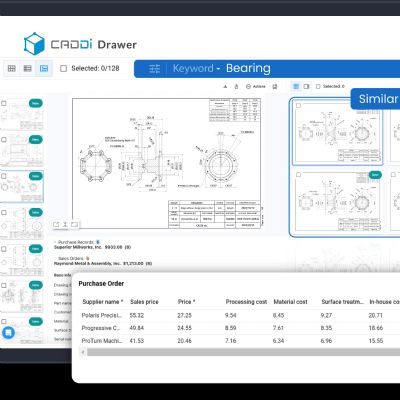

Key Financials-module updates: improved grid components that enhance data visibility and user experience; advancements in the purchase-order and accounts-payable matching process; streamlined processing of open items in accounts payable; updated and improved payable transactions process; new Salesforce Lightning page for accounts-payable users for more-efficient payments processing; and more.

Stamper Revels in the Enhanced Process Visibility Delivered by Cetec ERP System

Metal-stamping manufacturers strive to achieve structured work schedules, controlled inventory and detailed traceability. The path to achieve those goals often includes visibility in planning, ordering and production.

|

On August 13-14, 2024, MetalForming magazine and the Precision Metalforming Association will host an Industry 4.0 Forum and ERP Shootout, an in-person event held at PMA headquarters in Independence, OH. This informative forum on Industry 4.0 applications for metal formers and fabricators includes a tour of some of the industry’s leading ERP software systems. Day one of the event features Industry 4.0 presentations as well as a networking reception. Day two features in-depth software demonstrations from four leading ERP suppliers: Plex, by Rockwell Automation; Epicor Software; ECI Software Solutions; and DelmiaWorks. Users will participate in lively group discussions designed to address any questions regarding software features and functionality. More details and to register. |

Case in point: Fong Kai Industrial (FKI), a stamper in Carrollton, TX, serving a variety of OEM customers including HP, LG and Ford. To improve visibility into its processes and avoid attempting to patch together separate software systems for each area at the company, the firm recently brought in a new ERP system, Cetec ERP. With Cetec ERP, FKI has found an all-in-one system with the strength to address each area on its own while staying integrated on one simple, centralized platform.

The move to Cetec ERP was prompted by the expansion of FKI’s customer base, which grew from repetitive stamping into a diversified product mix. That expansion challenged FKI’s management team to move its business operations forward while working on a melting pot of spreadsheets along with two different accounting-software interfaces—QuickBooks and Microsoft Dynamics/Great Plains.

For an upgrade, the FKI management team sought to achieve controlled production planning with complete traceability from the creation of an order through its build process, all the while demanding visibility of inventory requirements. It needed an intuitive, integrated system to help track its entire business on a unified platform, from quoting to production, and to shipment of final product. It wanted to avoid the issues that can occur when any step of production becomes lackluster: lost efficiency, the shop floor falling behind or backtracking in material planning.

Bring on Cetec ERP, which has moved FKI onto a paperless ERP platform that connects engineering, inventory, production, accounting and more. This improved visibility, company officials report, allows FKI to leave behind its lagging, glued-together systems and basic spreadsheets. Instead, it creates an opportunity to visualize its entire business process on a single, complete platform. It’s now able to visualize vendor-consignment warehouse inventory for upcoming orders, detail build operations for live work orders on the floor, and track purchase orders driven by an active material-resource-planning (MRP) function within the Cetec ERP system.

Says Derek Dooley, FKI president: “We transitioned from another product that was overhead-intensive, and where shop-floor management, MRP and traceability were our pain points that needed addressing. Cetec provided the solution to those issues.”

Epicor Drives Productivity Increase at CenterLine

Privately held CenterLine Ltd., Windsor, Ontario, Canada, builds custom, automated welding and assembly lines as well as standard brand products for fastener welding, resistance welding, and metal joining, forming and coating applications. Customers include OEMs and Tier One automotive manufacturers, and mass-transit, aerospace and defense industries.

An outdated MRP application had been impacting manufacturing and procurement efficiencies, and CenterLine management had determined that it no longer could support the business and its growth trajectory. The company manages some 5000 manufacturing jobs every week across its four-building manufacturing site—numbers too large for the incumbent system. Following an extensive evaluation process, CenterLine decided on an Epicor manufacturing ERP solution.

An outdated MRP application had been impacting manufacturing and procurement efficiencies, and CenterLine management had determined that it no longer could support the business and its growth trajectory. The company manages some 5000 manufacturing jobs every week across its four-building manufacturing site—numbers too large for the incumbent system. Following an extensive evaluation process, CenterLine decided on an Epicor manufacturing ERP solution.

The solution: Epicor Kinetic, Epicor Enterprise Content Management (ECM) and Epicor Quick Ship. Kinetic, the foundation of the company’s operations, supports manufacturing, finance, supply chain and human resources, among others. ECM is an AI-based document-management application, and Quick Ship automates many administrative actions associated with shipping products to customers. For example, staff used to go to a shipping website to manually enter shipping details and print a label. Quick Ship does this automatically, which, with hundreds of shipments a day, saves significant time.

Simple-to-use APIs enable CenterLine to integrate several key applications with Epicor. These include product-lifecycle management, materials management and payroll applications where data automatically exchange with Epicor, eliminating the need for time-consuming and manual data input.

“The Epicor API makes it easy to add features and integrations,” explains Darryl Beneteau, CenterLine COO. “We have several self-developed systems, and integrating these became much more straightforward and easier than before.”

CenterLine spent approximately one year deploying the Epicor solution, involving the full Epicor Kinetic platform across four separate manufacturing buildings, a CRM application, a sister company and 286 individual system processes.

“The implementation was incredibly smooth—we had three Epicor consultants supporting us, and they were fantastic,” says Beneteau. “We went live on a Monday morning and, remarkably, only missed half a day of shipping. There were no major issues.”

CenterLine benchmarked manufacturing processes before and after implementing Epicor and documented a multitude of improvements. For example, steps-to-complete across 82% of jobs were reduced by 10%—significant savings across 5000 jobs/week.

Quick Ship has helped to deliver other improvements, allowing CenterLine to process large and increasing volumes of sales without additional staff.

“Before, we processed around 150 sales lines/day,” says Beneteau. “Now, we have nearly tripled our daily throughput and recently hit 420 sales lines in one day.”

Lot tracing and tracking also benefited through the ERP solution. CenterLine uses specialized copper and metal powders in its products and consumables, with material quality varying. Should a customer report a material problem, Epicor records the information and then automatically back-tracks the material lot to identify where it came from and if other customers used it.

“CenterLine is a manufacturer, and the efficiency improvements we have gained with Epicor are fundamental to the business,” Beneteau says. “The benefit is not just cost savings, but also increasing volume and getting more done quickly. CenterLine has a growth trajectory, and increasing capacity is critical. The growth inhibitor was processed, and Epicor has alleviated that bottleneck.”

Job Shop Ties Growth to Effectiveness of Global Shop Solutions ERP

Founded in 1996 by Richie Richmond, Forma-Fab Metals, Inc., a custom job shop headquartered in Mebane, NC, employs sheet metal punching, laser cutting, press brake forming, welding and more to churn out components for medical applications, high-tech electronics, point-of-purchase kiosks and standard industrial/commercial enclosures.

To accelerate company growth, Richmond recognized that the disjointed spreadsheets and software systems employed to manage the business at that time could not support his objectives. The solution: ERP software from Global Shop Solutions.

To accelerate company growth, Richmond recognized that the disjointed spreadsheets and software systems employed to manage the business at that time could not support his objectives. The solution: ERP software from Global Shop Solutions.

While scouting out possible software, “we instantly were sold on Global Shop Solutions’ powerful Advanced Planning & Scheduling (APS) module,” says Ron Tedder, director of operations for Forma-Fab Metals. “APS gives us a lot of flexibility in how we manage our production schedules. We easily can manipulate the data to see what will happen if we change the existing schedule. The visual aspects of APS make it easy to absorb and understand all of the data. We can look at current and future capacity by workcenter. And, we can track the efficiencies on every job.”

Soon after implementing Global Shop Solutions ERP software, Richmond began noticing dramatic improvements in key areas of the business, including MRP. Switching from the old manual process sheets to Global Shop Solutions’ integrated system dramatically reduced the time required to purchase the raw materials and components needed to run the business, according to Richmond. At the same time, billing, shipping and invoicing accuracy improved significantly, especially in terms of reconciling billed and shipped parts with invoiced parts.

“We’ve now discovered that shipping parts under the same system in which they are invoiced eliminates those ‘black holes’ where some parts are shipped but never are invoiced,” says Richmond. “You always want to get paid for what you ship, so I was happy to see improvement in that area.”

The ability to review job history easily and evaluate recent work orders for specific jobs quickly improved job costing. It also helped to determine when Forma-Fab Metals had correct pricing structures in place and when margins needed adjusting. In addition, when customers call in with an “I need it yesterday” job, the ERP software enables Forma-Fab Metals to respond more quickly.

“When somebody needs a part quickly, I can look at the capacity in the APS module and identify any gaps in the schedule,” says Tedder. “As a result, I can promise delivery more quickly than I would have in the past.”

Perhaps most importantly, Richmond and his team began receiving needed information from its ERP software to make better decisions for customers and for the company.

“The scheduling information from APS enables us to make accurate decisions about when we can send a product out the door,” says Richmond. “This allows us to take on business that we know we can produce and turn away jobs that would cause too much disruption to the schedule.”

More numbers to consider: Since implementing this ERP software, Forma-Fab Metals has experienced a 50% reduction in finished goods and work in progress (WIP) inventories, and a 20% reduction in raw-materials inventory.

Dura-Shiloh Standardizes Data Across 15 Facilities, Limits Material Variance with Plex ERP

Dura-Shiloh, headquartered in Auburn Hills, MI, and comprising 38 facilities in 13 countries, supplies the automotive industry worldwide with products ranging from space frames and cross-car beams to seating systems and steering components. Its most recent expansion in North America: a manufacturing site for electric-vehicle battery enclosures.

With rapid business expansion, Dura-Shiloh management realized that in North America alone, the manufacturer’s facilities were running seven different ERP Systems, bringing difficulties in accessing consistent data from plant to plant.

“We spent more time looking for the right data and cleaning it than we did capturing the data,” says Terry McKinney, director of digital transformation.

This led Dura-Shiloh to switch to a single ERP system to increase productivity and connectivity—a user-friendly solution that could connect multiple facilities.

Dura-Shiloh partnered with Plex Professional Services to build and execute an implementation plan deploying a standard solution model across its facilities. Since the initial Plex ERP implementation, Dura-Shiloh has fully implemented 14 additional plants. McKinney described these implementations as “flawless” and stated that now, “everybody can talk the same talk.” With one ERP system in place, these Dura-Shiloh facilities have a common language with all team members on the same page. Not only has this enabled streamlined communication, but connectivity has improved significantly, report Dura-Shiloh officials.

Dura-Shiloh’s Plex implementation yielded positive results quickly. For example, physical inventory is checked on a yearly basis. After its first physical inventory check post-Plex implementation, one facility reported a material variance of less than 1%.

From one implementation to the next, the Dura-Shiloh team has become more accustomed to the process and has gained more confidence. The learning curve of the initial implementation helped the firm prepare for future acquisitions and a transition to a high level of self-sufficiency. During the first two implementations, Dura-Shiloh had a Plex delivery consultant available onsite to answer any employee questions. After working closely with Plex and developing a strong internal implementation team that met consistently and provided support to the team as needed, Dura-Shiloh felt confident moving forward with more limited Plex assistance.

Given that Dura-Shiloh implementations are performed on a plant-by-plant basis, the team has been able to carry out preliminary meetings with each plant prior to ERP implementation. An additional kick-off meeting also occurs at an implementation process’ start, ensuring proper outlining of all process steps and understanding of the timeframe and expectations by everyone. All associates on the plant floor are trained directly on the ERP system, further ensuring success during each transition.

Through a strong executive sponsorship and a centralized governance model, Dura-Shiloh has maintained a common configuration and deployment approach throughout the rollout. This allowed live ERP deployment at each site in less than 16 weeks. MF

View Glossary of Metalforming Terms

See also: Global Shop Solutions, Epicor Software Corp., Rootstock Software, Plex By Rockwell Automation, Cetec ERP

Technologies: Management

Jeff Cash, CEO of Architectural Fabrication, learned the importance of proper business scaling and organization when working for a 2000-employee electrical contractor after graduating from Texas A&M. Difficulties in navigating archaic systems in this organization was a pain point that stuck with him.

Jeff Cash, CEO of Architectural Fabrication, learned the importance of proper business scaling and organization when working for a 2000-employee electrical contractor after graduating from Texas A&M. Difficulties in navigating archaic systems in this organization was a pain point that stuck with him.