Activating the High-Alarm Setpoints

With the stop-circuit issues addressed, let’s discuss the high-alarm settings. Many units have a Setup mode that acts like a bypass switch—valuable when placing a die into the press. This allows the tonnage monitor to start a new job without triggering a nuisance alarm during setup.

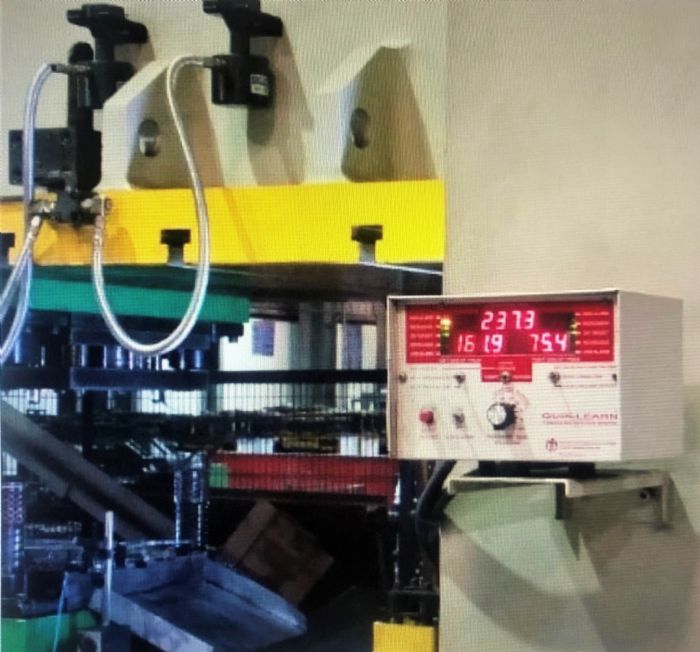

However, a tonnage monitor unknowingly can be left in this mode and will not provide protection during light-tonnage jobs. For example, with the monitor in Set Up mode, a 1000-ton press will not stop on an overload until its force exceeds 1000 tons. The unit must operate in Run or Automatic mode to activate the high- and low-tonnage limits. A Learn function on a tonnage monitor provides great help in setting precise limits for the particular job being run. A 1000-ton press might be running a job at 200 tons. This Learn function, set at 20 percent, would “learn” the high limit of 240 tons instead of using the maximum of 1000 tons. Most tonnage monitors without a Learn function still offer a method to adjust the high- and low-tonnage limits. For example, an operator can dial it in manually at 240 tons to activate the high-alarm setpoint.

However, a tonnage monitor unknowingly can be left in this mode and will not provide protection during light-tonnage jobs. For example, with the monitor in Set Up mode, a 1000-ton press will not stop on an overload until its force exceeds 1000 tons. The unit must operate in Run or Automatic mode to activate the high- and low-tonnage limits. A Learn function on a tonnage monitor provides great help in setting precise limits for the particular job being run. A 1000-ton press might be running a job at 200 tons. This Learn function, set at 20 percent, would “learn” the high limit of 240 tons instead of using the maximum of 1000 tons. Most tonnage monitors without a Learn function still offer a method to adjust the high- and low-tonnage limits. For example, an operator can dial it in manually at 240 tons to activate the high-alarm setpoint.

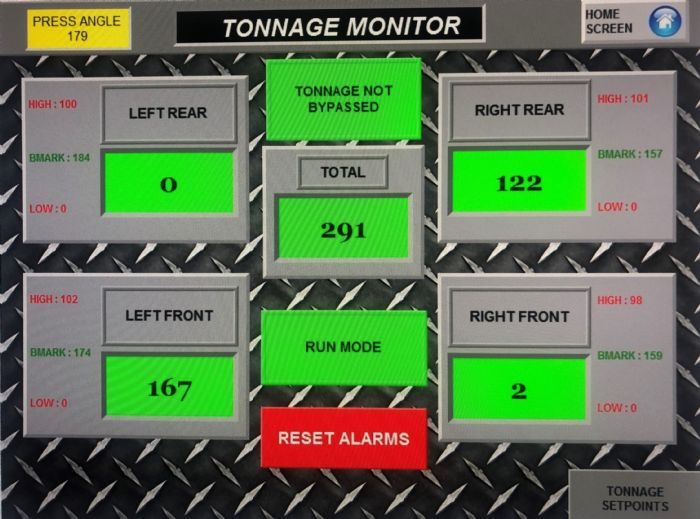

Changing Limits on PLC-Based Units

PLC-integrated tonnage monitoring offers expanded capabilities and enables automatic setting of limits for each die. Recently I worked at a plant with a highly skilled maintenance technician who had no idea how to change the limits on the PLC-based tonnage monitor. These limits were set at the tonnage capacity of the press. The PLC system still needed to be programmed for a specific job recipe, just as with die protection, programmable limit switches and shut height. Otherwise as mentioned, the values would be set to the tonnage capacity of the press. In this case, with a simple PLC program change, the tonnage parameters could be saved, recalled and loaded automatically with a job change.

Help Available for Tonnage Setting

Activating the alarm and limits makes tonnage monitors valuable tools in a stamping plant. A good supplier can provide experienced technicians to ensure proper settings. For its part, Toledo Integrated Systems has these technicians on staff, and also offers a simple ‘soft-calibration training’ process. Here, technicians reset the calibrated settings, address the stop circuit and train operators on how to activate alarm limits. Summarizing, there’s no better time than the present to use your tonnage monitors effectively. It’s easier than you think. MF

View Glossary of Metalforming Terms

See also: Toledo Integrated Systems

Technologies: Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Press-Line Controls Under One Umbrella-An Ideal Solution

Lou Kren September 27, 2024

When properly installed and operating, tonnage monitors perform vital functions that help ensure production of quality parts, while helping to eliminate damage to tooling and presses. Tonnage monitors can extend the life of presses and dies by preventing excessive hard hits, and also can be used to determine the minimum amount of force needed to form a part. An ideal monitor enables the setting of tonnage capacity as well as high- and low-tonnage setpoints. Should the setpoints be crossed, the press will stop.

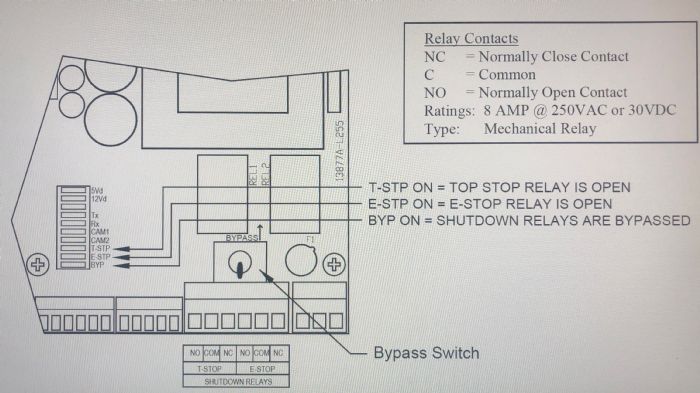

When properly installed and operating, tonnage monitors perform vital functions that help ensure production of quality parts, while helping to eliminate damage to tooling and presses. Tonnage monitors can extend the life of presses and dies by preventing excessive hard hits, and also can be used to determine the minimum amount of force needed to form a part. An ideal monitor enables the setting of tonnage capacity as well as high- and low-tonnage setpoints. Should the setpoints be crossed, the press will stop.  Typically, such conditions result in a technician returning to recalibrate the units. The technician recalibrates with load cells, but usually tweaks the values only by about 5 percent. Unfortunately, this recalibration fails to address the real problem, as the units still do not stop the press due to tonnage overloads.

Typically, such conditions result in a technician returning to recalibrate the units. The technician recalibrates with load cells, but usually tweaks the values only by about 5 percent. Unfortunately, this recalibration fails to address the real problem, as the units still do not stop the press due to tonnage overloads.

Video

Video