Topology Optimization + Advanced Lattice Structure

DMG Mori engineers completely overhauled the component’s design by combining topology optimization with field-driven design techniques and advanced lattice structures.

“With nTopology, we were able to create a powerful and unique additive design. It wouldn’t be possible to create such a component with a traditional CAD system,” explains Martin Blanke, an AM project engineer at DMG Mori. The primary goal of the project: develop a lightweight design with the same external form factor as the original assembly but with a reduced number of components and weight, which meant finding a way to maintain the original structural profile while removing as much material as possible from the interior.

“With nTopology, we were able to create a powerful and unique additive design. It wouldn’t be possible to create such a component with a traditional CAD system,” explains Martin Blanke, an AM project engineer at DMG Mori. The primary goal of the project: develop a lightweight design with the same external form factor as the original assembly but with a reduced number of components and weight, which meant finding a way to maintain the original structural profile while removing as much material as possible from the interior.

Early in the design process, Blanke and his team decided on variable shelling and latticing as the best way to reduce the original design’s weight. However, performing these tasks in a timely fashion would be nearly impossible using traditional CAD tools.

Blanke explains: “With our traditional CAD system, it was only possible to shell this component with a constant thickness of 2 or 3 mm, but we found our solution in nTopology.”

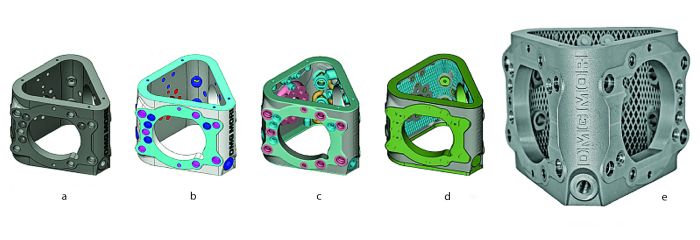

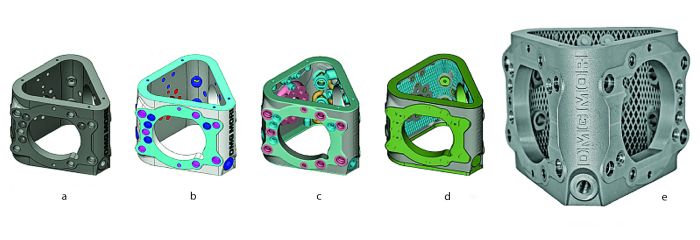

nTopology’s field-driven capabilities helped Blanke and his team overcome this bottleneck. Their process:

- Color-code all surfaces of the original design in CAD, each color corresponding to a different subsystem and later used as an input parameter in the topology-optimization software to determine the thickness of each section.

- Import the CAD file in nTopology and shell each section before combining them into a single body. The thickness of the outer shell was driven by topology optimization to maximize its stiffness.

- Fill the interior volume with a conformal lattice to increase the part’s structural strength and create a support structure for AM. Using nTopology’s engineering simulation tools, the team rapidly iterated to select the optimal lattice.

Design Automation with Color-Coding

Instead of just designing a one-off lightweight component, the design team developed a robust and reusable optimization process. It based the reusable workflow on the color-coded surfaces of the imported CAD body. First, the team defined colors for the surface of each subsystem in an external CAD system: blue for the pneumatic inlets and outlets, yellow for the pneumatic channels, red for the interfaces with the robot, purple for mounting points, green for contact surfaces, and white for the external surfaces.

It then used the color property in nTopology to select relevant surfaces and develop a reusable workflow. If the input geometry changed in future iterations or other projects, the team would only have to import the new CAD file and the optimization process would automatically rerun.

An essential design requirement: The external form factor of the original design needed to remain unaltered. The same restriction applied to the contact points with the arm and end effector, the pneumatic system’s inlets and outlets, the mounting screws for the electronics, and the cabling holes. While topology optimization could not be used directly as the final design, the team used the topology-optimization results to drive the thickness of the outer shell.

Using the color-coding system, the team automatically defined the design space for topology optimization. Then, the optimization-process result was used as input to create an outer shell of variable thickness, adding material where required.

“A big advantage of using nTopology,” says Blanke, “is that it’s possible to convert the result of the topology optimization into a useful model that can be used either directly or indirectly in another function.”

This process helped the team grasp some of the structural benefits of topology optimization without changing the part’s exterior.

With the exterior shell developed, the team turned to the structural and pneumatic systems, also seeking to reduce their weight and integrate them into the design. Using the color-coding system, Blanke’s team easily was able to apply a different constant shell thickness to each subsystem. For example, designers could assign pneumatic inlets and outlets a greater thickness than those specified for the pneumatic channels, a process not nearly as straightforward to perform with traditional CAD tools.

The last step of the process, which Blanke calls “one of the main advantages of using nTopology:” With the separate shells generated, the designs were then combined into a single body using a simple boolean union. The boolean union block joins multiple implicit bodies into one with optional blending between them to add fillets.

Conformal Lattice for Stiffness and Support

A few tasks remained, chief among them: Many interior features comprised large overhangs not conducive to metal AM, as the team sought to avoid excessive use of support structures and the tedious, wasteful process to remove them. Therefore, the engineering team used lattice structures to provide permanent support to all interior regions of the part. Additionally, the internal lattice structures increased part stiffness.

To identify the optimum lattice thickness, the team leveraged nTopology’s integrated simulation tools to automatically run multiple finite-element and lattice simulations, quickly evaluate the results and adjust specific parameters to iterate and optimize their design. The software’s integrated engineering simulation and design-automation capabilities saved Blanke’s team many engineering hours, as moving to a different software would only add complexity to the workflow.

With the design complete, only a few final details needed to be added to prepare for manufacturing and post-processing. For example, any holes and hollow areas in the final model could have led to imperfections during the AM process. So, Blanke and his team filled most of these sections with solid material that easily could be CNC-machined afterward.

After 39 hr. of metal AM in the Lasertec 30 Dual SLM machine, and then finishing using five-axis CNC machining, the team finally had four physical prototypes of its new lightweight design ready for testing in the robotic system. Early tests showed that the new component’s higher stiffness-to-weight ratio helped improve the robotic system’s handling precision by a factor of 16. Now the team is planning to apply a similar methodology in nTopology to lightweight other similar components.

“The unbreakable geometry, reusable workflows, and simulation-driven design are extremely powerful ways of designing for AM,” adds Blanke.

DMG Mori expects to begin commercially producing the metal-AM parts by press time. 3DMP

Article provided by nTopology.

See also: Ntopology

Technologies:

“With nTopology, we were able to create a powerful and unique additive design. It wouldn’t be possible to create such a component with a traditional CAD system,” explains Martin Blanke, an AM project engineer at DMG Mori. The primary goal of the project: develop a lightweight design with the same external form factor as the original assembly but with a reduced number of components and weight, which meant finding a way to maintain the original structural profile while removing as much material as possible from the interior.

“With nTopology, we were able to create a powerful and unique additive design. It wouldn’t be possible to create such a component with a traditional CAD system,” explains Martin Blanke, an AM project engineer at DMG Mori. The primary goal of the project: develop a lightweight design with the same external form factor as the original assembly but with a reduced number of components and weight, which meant finding a way to maintain the original structural profile while removing as much material as possible from the interior.