Optimizing Trim Lines Pays Off Big Time

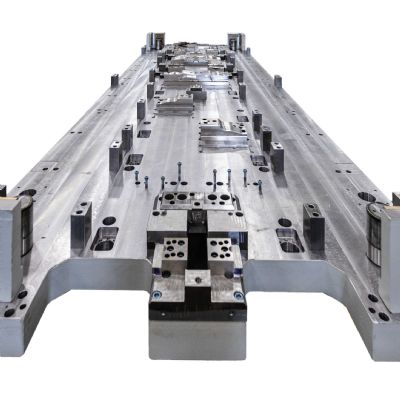

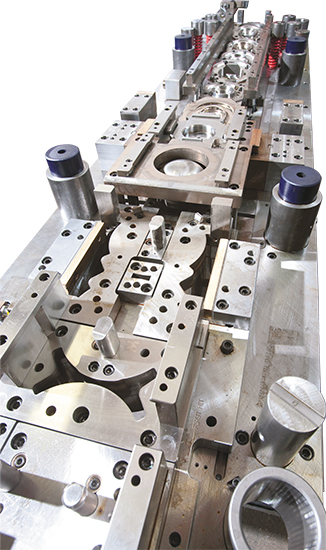

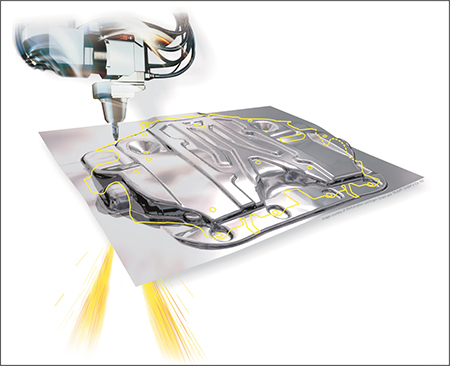

“I design tooling to support our inhouse operations, using the Trimplus software in a variety of ways, from testing small bent widgets to check springback, to folding, drawing and trim development of parts,” Newberg says.

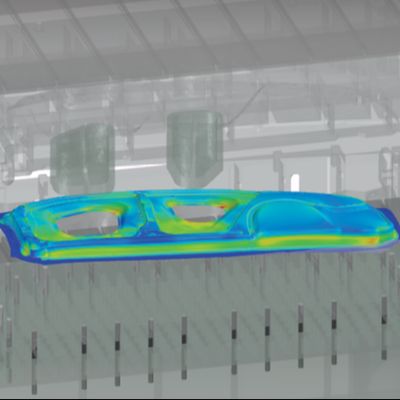

‘Virtual tryout’ is how he explains the software to those unfamiliar with it.

“I tell them that I’m trying out tools on the screen,” says Newberg, who goes on to detail how it saves time, labor and money at BTD. “Specifically with trimlines, it has saved us many iterations through tryout. We reduce the number of tryouts because we are not hitting a part, then adjusting the blank or trim edges, then going back to the press—I would guess a 30-percent-plus reduction in tryouts related to developing trimlines and blank edges.”

Work on one particular part highlights how BTD leverages such capabilities not only to meet customer demands, but to provide assistance that leads to more work down the road.

“Once we earned the opportunity to quote production on that part,” he continues, “we already had a good idea of the challenges we would face. Ultimately, due to information gained from the software, we decided on a preform, then trim, then final form to produce the part. Without the software, our gut feel was to crash-form the part, meaning splitting issues and a lot of tooling recuts. The software helped us upfront to develop our process, using the trimline-optimization capability to develop the trims. We took the project to a tryout press, made a couple of minor trim adjustments and then qualified the part. We cut steel for production after only two tryouts, whereas in the past we would have performed as many as 10 press tryouts just to dial everything in.”

Leads to Improved Customer Relationships, More Work

See where this is going? The benefits extend well past optimization on a particular part.

“The goal for BTD with this software is to reduce recuts and redesigns, and, as a result, tryout time,” Newberg says, with the example above illustrating success in reaching that goal. “That opens up our equipment and allows us to keep moving forward with original builds without having to backtrack for tool recuts and more tryouts.”

Key to all of it, according to Newberg: spot-on correlation between simulation and real-world results.

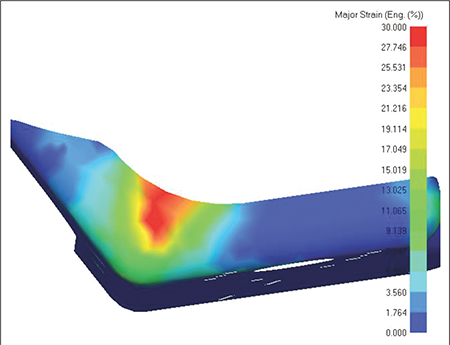

“If we see a certain percentage of thinning in the simulation and I check the parts off of the production floor, the simulation and the measurement are identical,” he says. “When we first used the software, given our experience, we went with our gut feel, hesitant to accept what the software showed. But as years go by and we compare the real world to simulation, we see the correlation.”Newberg finds that customers are more willing to redesign parts or make other concessions up front during design prior to any tool building. The ability to provide an increased level of part-forming knowledge at that stage can pay off later on when customers are looking for a part producer. And, the software assists this effort in another way through its reporting capability, according to Newberg.

“I can present the data in an easy-to-understand manner,” he says. “Customers do not need to know the stamping world or all of the process details. We can just show the results of simulation and they get it.” MF

View Glossary of Metalforming Terms

Webinar

Webinar