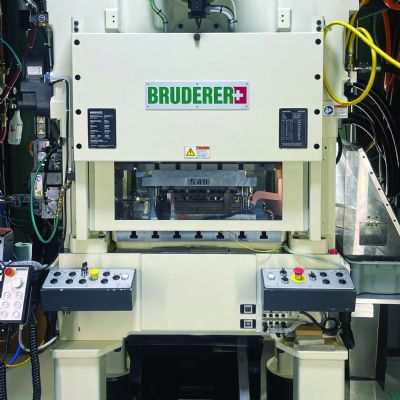

Alois J. Rupp, president of Bruderer Machinery Inc., says that even though accuracy can be maintained on rebuilt presses, the older machines can’t accommodate the new features that set newer technology apart. For that reason and others, the reconditioned machines did not make sense for Weiss-Aug.

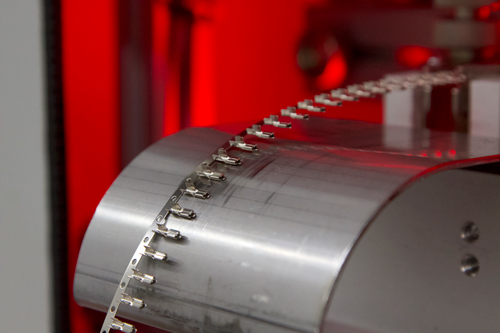

“In some cases, rebuilding machines for certain products makes sense; this wasn’t one of those cases,” Rupp says, explaining that Weiss-Aug’s stamped parts are small and complex, and rarely flat. Coined, formed and bent multiple times, tolerances are as tight as ±0.0005 in. while part quantities number in the millions. Materials used include stainless steel, beryllium copper, beryllium, phosphor bronze, nickel and other alloys.

“When we began running the same dies, making the same parts in the new presses, we couldn’t believe the improved consistency within production runs,” Cole states. “Not only were we able to increase press speeds, but most of all the new machines reduced die maintenance. Dies also had to be adjusted less frequently, reducing downtime. In summary, productivity rose significantly.”

Rupp notes a press feature that he says ensures consistency: the mass counterbalance system distributes the press’ forces more evenly throughout the machine, thereby maintaining its stability at high speeds.

Servo Shift

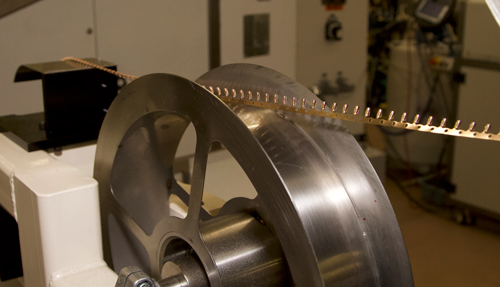

Initially, Bruderer delivered presses to Weiss-Aug with mechanical feed systems. However, Weiss-Aug quickly determined that it wanted the BSTA 200s with servos.

“Set up time is almost 50-percent faster,” Cole says. “The setup of a servo feed is very much automatic and foolproof. The parameters—stroke, pitch and pilot release—all of which were set manually on a mechanical press, now are keyed in at the initial setup and retained in the press library. Not only does this cut setup time, it guarantees consistent setups by eliminating personal preferences.

“My plan is to continue to upgrade to new technology as we move forward,” Cole continues. When asked what excites him most about the new equipment, he answers, “The challenge of achieving tight tolerances and making the parts that no one else wants to make. It’s very satisfying watching those parts come off of the press and thinking of all the brainpower that went into figuring that out the tooling and making it all work.” MF

Article supplied by Bruderer Machinery, Inc., Ridgefield, NJ; 201/941-2121, www.brudereramericas.com.

View Glossary of Metalforming Terms

See also: Bruderer Machinery, Inc.

Technologies: Coil and Sheet Handling, Stamping Presses

When engineers at Weiss-Aug Co., an East Hanover, NJ-based stamper, began noticing in 2015 that stamping dies, running in their 30-plus-year-old stamping presses, were showing their age, they knew something had to be done. The question: What?

When engineers at Weiss-Aug Co., an East Hanover, NJ-based stamper, began noticing in 2015 that stamping dies, running in their 30-plus-year-old stamping presses, were showing their age, they knew something had to be done. The question: What?