The Optimal Stroke Is the Shortest Possible Stroke

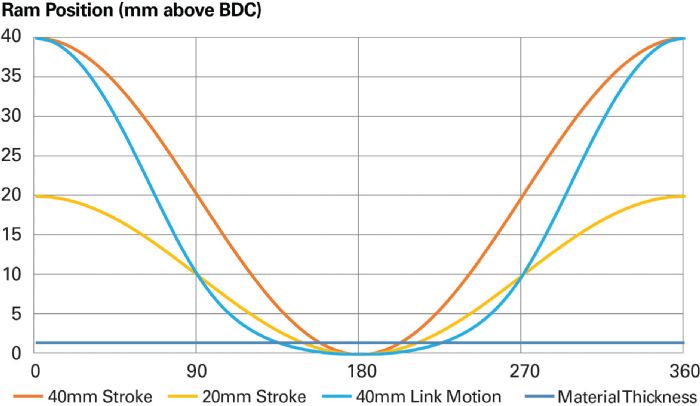

A careful analysis of the part to be shaped and the feed system will provide insight into the shortest possible stroke length for a given process. At any point during the crank rotation, one of the following occurs:

A careful analysis of the part to be shaped and the feed system will provide insight into the shortest possible stroke length for a given process. At any point during the crank rotation, one of the following occurs:

- Cutting, forming, etc.

- Material feeding

- Piloting

- Gap opening/closing to provide clearance for feeding.

Other operations, such as inspection or welding, can be incorporated into the cycle. This only should be considered when the value-add is greater than the reduction of efficiency at the press. In the tradeoff consideration, consider all of the factors discussed above.

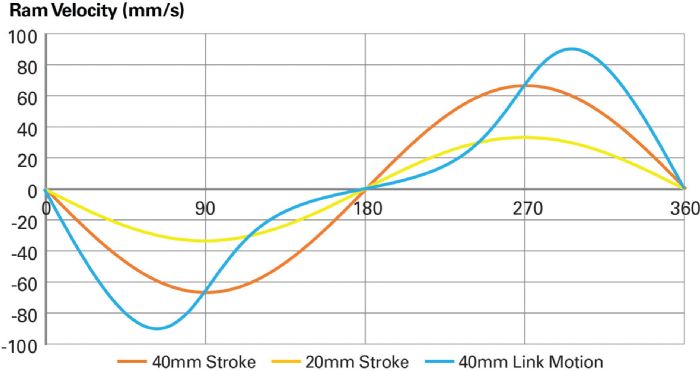

A shorter stroke yields:

- Fewer punch breakages in the tool

- Longer intervals between tool sharpening

- Better forming results

- Longer press life

- Less vibration

- Less noise

- Fewer nuisance faults.

Biases and assumptions in tool design or equipment selection can be difficult to detect and change. More obvious reasons for less-than-optimal stamping processes:

- Equipment is not used for its intended purpose

- Making a job work on available equipment

- Purchasing equipment that “would do the job”

- Purchasing new equipment at discounted price

- Repurposing existing equipment

- Operating conditions/tradeoff values have changed dramatically

- Production volumes/lot sizes have changed significantly

- Product specifications/part tolerances have been tightened

- Production requirements for quality, certifications, packaging and delivery have changed

- Equipment is outdated

- Newer technology not utilized

- Lack of automation

- Lack of spare parts

- Decreased serviceability

- • Equipment has lost its precision from when it was new

- Damages due to operating error

- Material fatigue, improper repairs

- Normal wear

- Past modifications.

How to Improve the Stamping Process

Efforts to optimize start with an open mindset and a willingness to allow discoveries to effect change. It requires an environment where we replace assumptions with reason, and re-evaluate prior decisions based on changes in the operating conditions. Hiring an outside expert that provides an unbiased analysis and technological insights can be helpful. Sometimes simple remedies can make a significant difference. MF

Article provided by Sangiacomo Presses Americas, LLC.

View Glossary of Metalforming Terms

See also: Sangiacomo Presses Americas, LLC

Technologies: Stamping Presses

Many stamping operations occur under less-than-ideal conditions, and the impact of stroke length often is overlooked. Four reasons why metal stampers should strive to use the shortest possible stroke:

Many stamping operations occur under less-than-ideal conditions, and the impact of stroke length often is overlooked. Four reasons why metal stampers should strive to use the shortest possible stroke: