Perfect the process. “In the prototype stage, you can make all the painful mistakes so that by the time you get to production, there are no surprises,” Kuhr says. “At the end of the day, so much money can be saved.”

“When we receive CAD part data that is not ready for production manufacturing, that is where our team comes into play to help ensure that the final part is manufacturable and at a feasible price point,” Kuhr adds.

One of the successful approaches PTM takes that may be

unique is that when the company makes a prototype, it mirrors the final

stamping processes closely.

“In prototyping, you can make anything. Everything in prototype is capable because you have time to shape it, to bend it, and you can use hand tools to put the part in specification. You can make things that would never be feasible to make in production,” Kuhr says.

Save money. Another PTM goal for prototyping is to find ways to eke cost out of the part. “We work with the customer, and its engineering and quality teams to determine what is acceptable while meeting specifications and building quality into the product,” Kuhr says.

Save money. Another PTM goal for prototyping is to find ways to eke cost out of the part. “We work with the customer, and its engineering and quality teams to determine what is acceptable while meeting specifications and building quality into the product,” Kuhr says.

Russell-Kuhr offers an example. “A customer might want to prove out the same part in three different metal thicknesses to determine how thin the material can run and still meet design criteria,” she says. “When you run 30 million production parts of a given part number, reducing your metal thickness saves a lot of money.”

Develop costing models. Another prototyping objective is to develop costing models. This is especially relevant as more electric vehicles (EVs) move into the mainstream, Russell-Kuhr says. “So many EV companies are going to be launching in the next few years, and there’s no way on God’s green earth they’re all going to be winners. Most production volumes will be very low.”

PTM is working with an EV OEM in the prototype stage to help

it gear its costing model for low-volume production stampings and assemblies at

an initial low-volume rollout so that it is mutually profitable, according to

Russell Kuhr.

“We’re working out where they can make money and we can make money,” she says, “because no one knows exactly how well and how soon these EVs and hybrids are going to sell.”

Develop cost-sensitive prototype tooling. It’s essential at the prototype stage to be able to design and build tooling to meet customer needs. At the same time, much is learned from the prototype tooling that can benefit the production tooling. Most cost avoidances can be made at this stage in prototype to develop lessons learned and carry over to production tooling and processes. The benefits of prototyping can outweigh high engineering costs of production tool changes.

Develop cost-sensitive prototype tooling. It’s essential at the prototype stage to be able to design and build tooling to meet customer needs. At the same time, much is learned from the prototype tooling that can benefit the production tooling. Most cost avoidances can be made at this stage in prototype to develop lessons learned and carry over to production tooling and processes. The benefits of prototyping can outweigh high engineering costs of production tool changes.

“When a customer comes to us with a low-volume part, we can’t be competitive with production tooling costs,” Kuhr says. “Our advantage is that we know production and prototype and how to design and produce robust prototype tools at a lower cost. Then we take it back to the secondary form stations. We form the geometry characteristics into the part through a series of stamping stations.”

The largest press at PTM: a 2000-ton-capacity model.

“We’re forming fenders, doors, hoods and Class A surfaces with that press,” Kuhr says. “We provide assemblies on closures as well as highly complex assemblies such as front-end and rear rails.”

Normally it takes only two or three hits to form a door or

fender, with a couple of laser trims in between. But each part is unique, and

the number of stations varies for each prototype process. One operation had 28

forming stations after it was laser-blanked to become a finalized part.

On occasion prototype parts need hand qualifying, but

simulation software mitigates that.

Small prototypes. The small-prototype process starts similarly to the large prototypes, with some significant differences.

“It’s similar to our large-prototype process in that we create a developed blank which is laser-cut,” Kuhr says. “Then we use a series of line dies to form the part. But we mirror our stamping production process more closely throughout our small-prototype process.

“Think of a progressive die, and each station is pulled out and set in a series of small presses to form the part to its specifications,” he adds. “We perform each of the operations in a number of small, single presses. This produces parts with characteristics similar to mass production.”

Small parts. The design, engineering and manufacture of small prototypes is quite different from large prototypes, according to Kuhr.

“Prototyping brackets, clips and metal fasteners is totally different than how we make a fender or a door,” he says.

“Our small-prototype shop stamps parts so small that you literally can put 50 of them in the palm of your hand—we make jewelry over there,” Russell-Kuhr adds.

In the design stage, engineers always look for ways to

consolidate parts, offers Kuhr. At the same time, the forming of the small

parts is simplified. The small-parts forming is limited to bend radiuses and

angles, mainly.

“A small bracket might have a 90-degree bend in it, while a large prototype has all kinds of forms that you could never do with the small prototype process,” Kuhr says.

Prototype to Production

Unsurprisingly, PTM welcomes running the prototype parts that

it developed in large-volume production runs.

“We take on those low-volume jobs—a few hundred parts or more and before you know it, we’re quoting large-volume production,” Russell-Kuhr says. “That’s kind of how we migrated prototyping into production and it made a natural fit for our business model growth.”

“We take on those low-volume jobs—a few hundred parts or more and before you know it, we’re quoting large-volume production,” Russell-Kuhr says. “That’s kind of how we migrated prototyping into production and it made a natural fit for our business model growth.”

About half of the jobs for small-part prototype programs at

PTM go into production tooling and production facilities; however, once the

large prototypes are perfected, the OEMs usually perform production.

“We might prototype a door for an OEM, but its own production facility will run production and our work ends at the prototype stage,” Kuhr says. “Automakers like to control their Class A process, especially outer skins.”

Remarks Russell-Kuhr: “We feel that our competitive advantage is offering both prototyping and mass production, which provides our customers a better result for their mass production process.”

Finding a Way

Because so many unknowns accompany prototyping,

inventiveness is required.

“We always find a way,” Russell-Kuhr says.

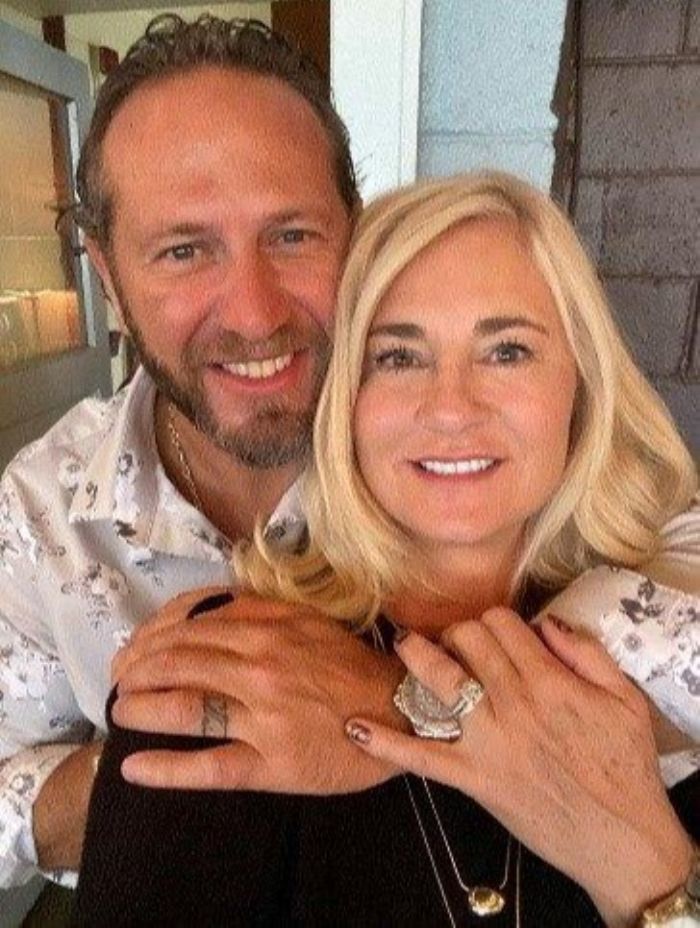

Finding a way is rooted in the family-owned company’s origins. That family legacy began with Donna’s father, Charlie Russell, whose scrappy ingenuity transported him from a poor cotton-picking sharecropper in Mississippi to starting a small prototype shop in Michigan with one customer to help him start his new venture. Russell passed away in 2016; however, his legacy lives on as the shareholders and employees have continued to carry on that can-do team spirit.

“Dad started with nothing and applied his wits and ingenuity to solving problems the best, quickest, and least expensive way—and just helping his customers,” Russell-Kuhr says. “That was always at my dad’s heart. People have a problem, and we’re going to find solutions for them. He would do whatever he needed to make them happy, and my mom would come in and help him.

“We have a code of honor at our company,” she continues. “It’s about how we want to conduct business with our customers, each other as employees, and our suppliers, no matter what the conditions are—if the economy isn’t doing well, or there’s a pandemic. Our number-one code of honor is ’deliver exceptional performance and peace of mind to our customers.’ We trust that our corporate values will carry on in our next generation of family and those new people who succeed us. We believe that this is what keeps our company together through the good times and the not-so-good times.” MF

Industry-Related Terms: Blank,

CAD,

Die,

Form,

Forming,

LASER,

Model,

Prototype,

Run,

Thickness,

FormingView Glossary of Metalforming Terms

See also: Faro Technologies Inc.

Technologies: Stamping Presses

Most stamping manufacturers conduct some prototyping in their operations. Usually, it is offered as a service but not necessarily a revenue source. Rarely does prototyping comprise 50% of a stamping manufacturer’s business. Not only does prototyping sustain half PTM Corp.’s business, it is so sizable that it comprises two prototyping divisions.

Most stamping manufacturers conduct some prototyping in their operations. Usually, it is offered as a service but not necessarily a revenue source. Rarely does prototyping comprise 50% of a stamping manufacturer’s business. Not only does prototyping sustain half PTM Corp.’s business, it is so sizable that it comprises two prototyping divisions. Perfect the part. One goal of prototyping is to prove out the part. PTM might stamp three or four versions of a part and before the customers buyoff depending on size and complexity, according to Russell-Kuhr.

Perfect the part. One goal of prototyping is to prove out the part. PTM might stamp three or four versions of a part and before the customers buyoff depending on size and complexity, according to Russell-Kuhr.

Save money. Another PTM goal for prototyping is to find ways to eke cost out of the part. “We work with the customer, and its engineering and quality teams to determine what is acceptable while meeting specifications and building quality into the product,” Kuhr says.

Save money. Another PTM goal for prototyping is to find ways to eke cost out of the part. “We work with the customer, and its engineering and quality teams to determine what is acceptable while meeting specifications and building quality into the product,” Kuhr says. Develop cost-sensitive prototype tooling. It’s essential at the prototype stage to be able to design and build tooling to meet customer needs. At the same time, much is learned from the prototype tooling that can benefit the production tooling. Most cost avoidances can be made at this stage in prototype to develop lessons learned and carry over to production tooling and processes. The benefits of prototyping can outweigh high engineering costs of production tool changes.

Develop cost-sensitive prototype tooling. It’s essential at the prototype stage to be able to design and build tooling to meet customer needs. At the same time, much is learned from the prototype tooling that can benefit the production tooling. Most cost avoidances can be made at this stage in prototype to develop lessons learned and carry over to production tooling and processes. The benefits of prototyping can outweigh high engineering costs of production tool changes. “We take on those low-volume jobs—a few hundred parts or more and before you know it, we’re quoting large-volume production,” Russell-Kuhr says. “That’s kind of how we migrated prototyping into production and it made a natural fit for our business model growth.”

“We take on those low-volume jobs—a few hundred parts or more and before you know it, we’re quoting large-volume production,” Russell-Kuhr says. “That’s kind of how we migrated prototyping into production and it made a natural fit for our business model growth.”