Modular Die Cushion Extends Deep-Draw Die Life, Improves Accuracy

April 23, 2019Comments

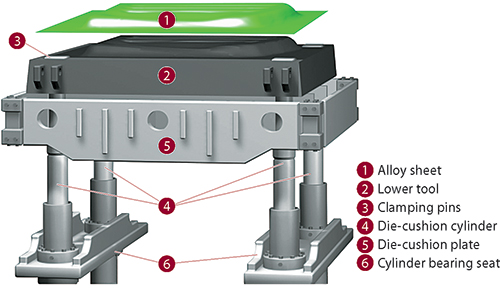

Moog has launched a new modular die cushion system to extend the life of deep-drawing dies, improve system reliability and reduce commissioning time for manufacturers. The new system includes a main cylinder with integrated position-measuring technology, accumulators, a hydraulic power unit and a number of manifolds. It features software libraries, and the control unit’s hardware components provide a compact, robust hydraulic arrangement that enables highly dynamic control, according to company officials.

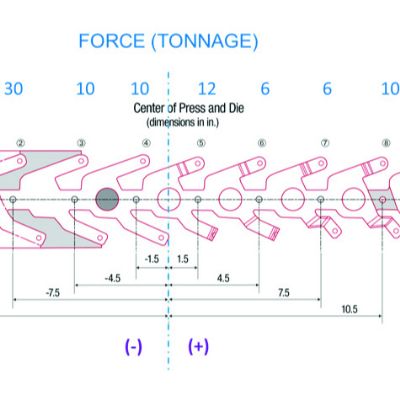

Moog’s design team integrated the manifold flange of the new system directly to the cylinder, where it connects to the main hydraulic accumulators via a separate adaptor manifold. The system reduces force overshoots, which can damage a press, and uses customer-specific force profiles to ensure high accuracy during drawing operations.

Maintenance professionals can easily access the system due to the unique mounting of its main components. And, flexible layout options for integrating the manifold, reportedly requiring comparatively little piping, helps users lower maintenance and piping costs.View Glossary of Metalforming Terms

See also: Moog Inc.

Technologies: Tooling