Process Feasibility and Material Utilization in Sheet Metal Forming

June 20, 2024Comments

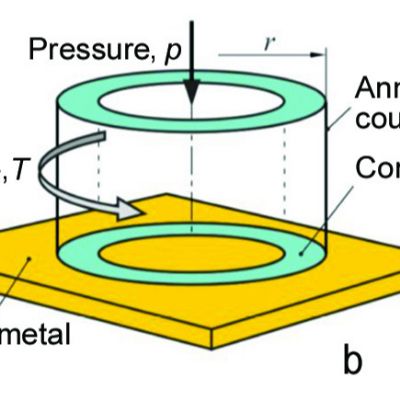

AutoForm-StampingAdviser enables users to evaluate part and process feasibility quickly and easily, as well as determine blank shape, material utilization and blank cost. The software provides valuable feedback on key stamping-quality issues, such as risks of splitting and excess thinning, potential for wrinkling and developed blank shape with its associated material costs.

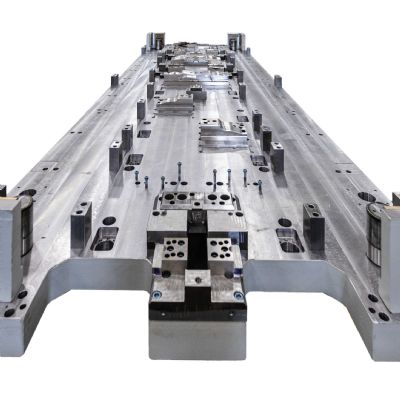

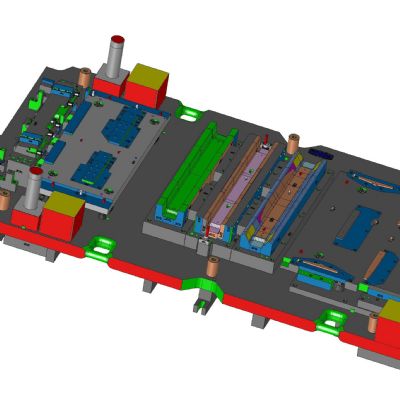

In the simplest application, AutoForm-StampingAdviser is used for early feasibility evaluations based on part geometry alone, without considering tool geometry. For these analyses, the software allows users to modify the part and, when needed, automatically generate a blankholder surface and a schematic addendum. In a more advanced application, forming analyses and blank development are performed based on the draw-die 3D geometry created by AutoForm-DieDesigner.

View Glossary of Metalforming Terms

See also: AutoForm Engineering USA, Inc.

Technologies: Software