Scalable, Modular, Automated Sheet Metal Fabrication

November 7, 2024Comments

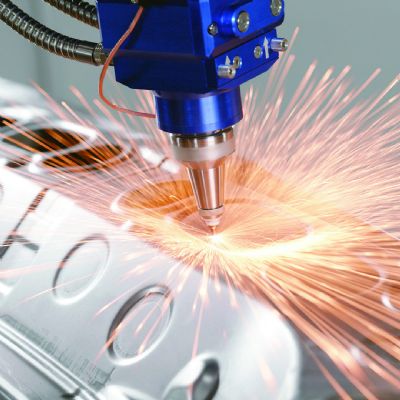

Scalable, modular integration of fabrication processes, via automation and software solutions, was the talk of EuroBlech 2024, held in October in Hanover, Germany. The message rang loud and clear at the Prima Power stand, which boasted the motto, “Evolve by Integration.” Highlights included the firm’s new 2D, 8-kW laser cutting machine, Platino Linear, outfitted with a Compact Server load/unload system; a robotic press brake cell combining a Prima Power eP Genius 1030 servo-electric press brake with an anthropomorphic seven-axis robot connecting the brake to a Night Train material-storage tower; and Prima’s PSBB (punch-shear-buffer-bend) flexible manufacturing solution, combining a Shear Genius EVO punch-shear machine and an Express Bender panel bender, all coordinated by Prima Power's proprietary and comprehensive software package.

Scalable, modular integration of fabrication processes, via automation and software solutions, was the talk of EuroBlech 2024, held in October in Hanover, Germany. The message rang loud and clear at the Prima Power stand, which boasted the motto, “Evolve by Integration.” Highlights included the firm’s new 2D, 8-kW laser cutting machine, Platino Linear, outfitted with a Compact Server load/unload system; a robotic press brake cell combining a Prima Power eP Genius 1030 servo-electric press brake with an anthropomorphic seven-axis robot connecting the brake to a Night Train material-storage tower; and Prima’s PSBB (punch-shear-buffer-bend) flexible manufacturing solution, combining a Shear Genius EVO punch-shear machine and an Express Bender panel bender, all coordinated by Prima Power's proprietary and comprehensive software package.

The Platino Linear boasts a 22% reduced footprint compared to previous models, as well as gas savings to 40%, reduced energy consumption and 96% maximum sheet utilization, according to company officials. The PSBB line provides integrated automation, enabling 24/7 automated production for kit, batch and mass production. By reducing low added-value manual operations, PSBB reportedly can quadruple production efficiency compared to conventional manufacturing cells.

And, pulling it all together is Prima Power’s software suite, combining its NC Express CAM package, with advanced toolpath generation and optimization algorithms, with its Tulus Office MES platform for production planning and monitoring, providing real-time insights and data analytics.

View Glossary of Metalforming Terms

See also: Prima Power North America, Inc.

Technologies: Cutting, Bending, CNC Punching