How Can I Apply Sensors To Prevent Tool and Die Damage?

September 23, 2024Comments

Many factors go into selecting the best sensor for a particular stamping operation: the style of the tool (box or spring stripper), the press type, speed and stroke, and secondary applications performed in the tool (riveting or tapping, for example). I could write a small book on each one. Start by defining the purpose, the different types available and their applications.

Note that while sensors in progressive dies are helpful, too many can lead to a disproportional number of false readings and production stoppages. Your team will then get into the habit of just resetting the sensors rather than recognizing when something is truly wrong and learning what causes the exact tooling damage that the sensors were installed to prevent. If you are creative in your sensor use, one sensor can detect multiple failure modes.

At high speeds—1000 strokes/min.or more—it’s virtually impossible to stop the press in time without making another hit due to ram inertia and the resulting effective stopping distance. Even if you signal the press to stop at 10 deg. past top dead center (TDC), at 1000 strokes/min. it still will be very difficult to stop the ram prior to 180 deg., during which time the ram has reached bottom dead center (BDC) and made another hit. The goal is to stop the press before you make another hit and cause tool damage.

Most mechanical press feeds have a fixed feed cycle of 120 deg. Some will allow you to vary the timing of starting and finishing feeding, but not the amount of time it takes to complete the feed cycle. Here the servo feed has a great advantage: At speeds to 600 strokes/min. the feed cycle can be changed to finish feeding as early as possible—perhaps before the press hits TDC, depending on the pitch or feed length. In this case you will have a lot more time to stop the press prior to making a mishit and damaging the tooling.

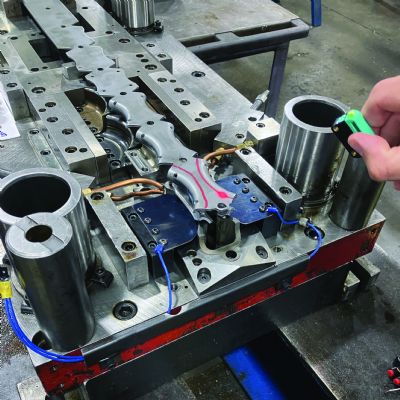

Sensor Types

Proximity sensors, the most common sensor type, sense the presence or absence of a feature in the part or tooling. Examples include the punch, stripper, progressive-strip location or a feature on the strip itself. These sensors prove useful for detecting a broken tap during in-die tapping and for sensing the end of raw-material stock. Pass-through proximity sensors do a great job sensing part ejection.

Laser sensors, which require an unobstructed line of sight between two points, find use in single-hit tools where an operator places and removes the finished part. The laser can detect if the part is seated correctly before the press can cycle. With thin parts it also can detect if the operator has accidentally loaded two parts, one on top of the other, forgetting to remove the previous part.