In addition, an AGV provides more freedom of movement than an overhead crane.

“AGVs can use alternate routes to avoid people or obstacles in aisles, for example,” says Oliver. “They drive sideways or diagonally, or spin in place—what we call omnidirectional motion. They can move dies or material into tight spaces, and reorient loads as needed through rotation of 90, 180 or any number of degrees. AGVs provide much more flexibility than cranes in load transport.”

Combining safety with productivity, AGVs prove their worth by removing humans from the transport equation, freeing them to undertake more value-added tasks.

“Moving dies or materials from shipping, maintenance or storage areas to their production locations is time-intensive and often involves long travel distances,” Oliver says. “These tasks may involve multiple employees. Automating die and material movement courtesy of AGVs frees employees for other work. Transporting material adds no value.”

Simple Route Programming and Operation

Contrary to some perceptions in the field, AGVs typically prove relatively simple to program and operate.

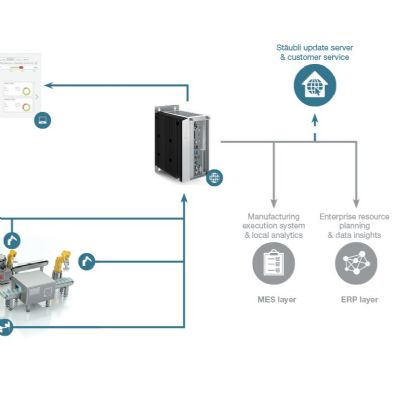

“After programming, no one needs to mind the AGV,” Oliver says. “And, tying an AGV to supervisory controls such as a manufacturing execution system makes it a hands-free operation. An AGV can retrieve a die and transport it to the desired location without human intervention.”

Route programming is a simple affair, according to Oliver.

“With a facility map on a computer, programming involves drawing a line for the desired AGV path,” he says. “Today we use natural-feature navigation to provide highly accurate and robust routing.”

Some AGVs (such as those provided by Stäubli) feature guidance via lasers mounted on the AGVs, as well as SLAM, or simultaneous localization and mapping.

“Lasers measure everything, and the SLAM algorithm uses those measurements to navigate,” Oliver explains.

What if an aisle closes for maintenance or a machine relocates?

“Go to the computer screen and draw a new path line to create a new virtual path to replace the old path,” says Oliver.

No need for an on-staff process engineer, automation engineer or robotics expert to handle AGV programming. Also, no need to place magnetic tape on the shop floor to mark a path and RFID tags to mark decision points. For complex AGV operations, automation integrators can assist.

As for charging, AGVs in general prefer to spend about 25% of a day on a charger, which presents no problems in most applications.

“An AGV can charge overnight, then run an 8-hr. shift, then charge up again,” says Oliver. “However, that’s not typical. An AGV might deliver a die then return to its home charging base—automatically—and wait for the next call.”

Handle Many Tasks

Ease of programmability and ability to remain charged give AGVs the flexibility to handle a variety of tasks throughout the plant. No need to dedicate an AGV for a single task unless that task consumes a lot of time.

“AGVs are not dedicated automation,” Oliver says, “and are considered collaborative mobile robots, meaning that they can work around people. That, and simple programming, make them very flexible in manufacturing environments. For example, an authorized employee can ‘drive’ an AGV through the facility using a joystick to generate a map, then from that map draw a route of allowable travel for the AGV and mark drop-off and pick-up locations. These locations, in the case of Stäubli’s programming routine, can be given common names such as ‘Maintenance Shop’ and ‘Press 1.’ Then the employee directs the AGV to take a die set from ‘Maintenance Shop’ to ‘Press 1.’ When the AVG completes that mission, it communicates that information and signals its readiness for the next project. Similarly, it can be programmed for its next mission, whatever that may be—anywhere in the plant, and along any route. That’s a huge advantage over fixed transportation mechanisms such as overhead cranes or tuggers.”

Safe to say that AGVs are maturing, and metal formers—from OEMs to tier part producers—can benefit in many ways. MF

View Glossary of Metalforming Terms

See also: Staubli Corporation

Technologies: Coil and Sheet Handling, Pressroom Automation, Tooling

“There are many AGV applications and a lot of adoption right now in metal forming operations,” says Oliver. “Applications include moving raw materials such as coils within the plant and to press lines, moving finished goods away from manufacturing equipment, and transporting dies to and from presses, to name a few. AVGs also feed assembly lines and carry chassis through body-in-white operations at automotive plants. If something needs to move from point A to point B, no matter the weight, AGVs can do it.”

“There are many AGV applications and a lot of adoption right now in metal forming operations,” says Oliver. “Applications include moving raw materials such as coils within the plant and to press lines, moving finished goods away from manufacturing equipment, and transporting dies to and from presses, to name a few. AVGs also feed assembly lines and carry chassis through body-in-white operations at automotive plants. If something needs to move from point A to point B, no matter the weight, AGVs can do it.”